A number of different instructional methods are used throughout the course to allow interactive learning and to give practical examples from manufacturing and service industry to enable the delegates to operate, select and troubleshoot control and safety valves upon course completion.

By the end of this course delegates will be able to:

The expert will suggest ideas and theories to the delegates and then encourage them to test out the ideas by the use of:

• Discussion

• exercises

• Case studies & DVDs

• group exercisess

• examples

Day1

Day 2

Day 3

Day 4

Day 5

Valve Troubleshooting

Valves Problems

High Pressure Drop

Water Hammer

Troubleshooting the Control & Isolation Valves

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI150-02 | 31-05-2026 | Riyadh | USD 5450 | |

| MI150-03 | 13-09-2026 | Muscat | USD 5450 | |

| MI150-04 | 14-12-2026 | Amsterdam | USD 6950 |

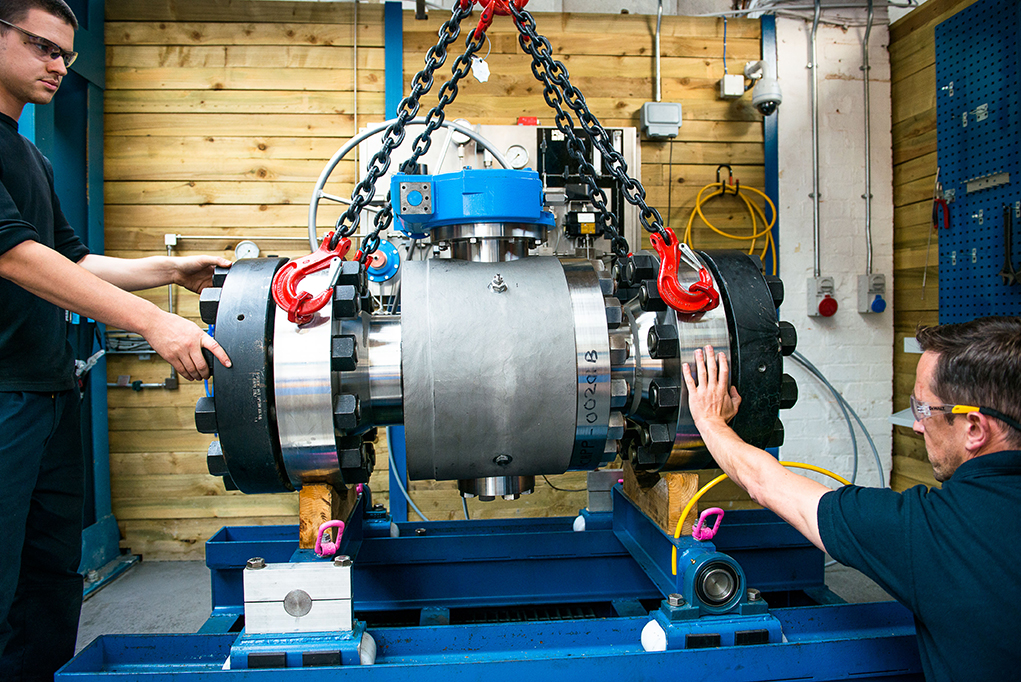

This course highlights the most important features and characteristics of control valves andactuators. Combinations of valves and actuators are used in just about every process around the world, and t ...

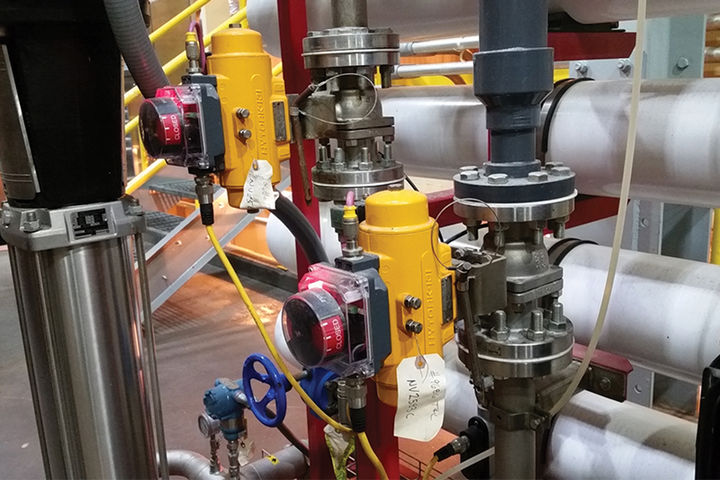

Power plant and other petrochemical industries do deal with different types of valves. All piping systems are fitted with valves for controlling purposes or safety requirements. Understanding the func ...

The overall purpose of this course is to provide engineers and senior technicians in their relevant fields with the applied knowledge that enables them to efficiently select, maintain or repair differ ...

The overall purpose of this course is to provide engineers and senior technicians in their relevant fields with the applied knowledge that enables them to efficiently select, maintain or repair differ ...

The course is designed for participants to understand the principles of the Types, function, Specification and classification of valves. Then cover the valves maintenance, troubleshooting and repair ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info