This course will feature:

By the end of this course, delegates will be able to:

Mechanical Engineers, General Supervisors, Consulting Engineers, Design Engineers, Foremen, Supervisors, Technicians, Maintenance Personnel, Engineers of all disciplines, Supervisors, Team Leaders and Professionals in Maintenance, Engineering and Production Managers, Maintenance Personnel, Heads of Maintenance and Operation, Chemical Engineers, Equipment Specialists, Technical Engineers, Operation Engineers, Planning Engineers, Process Engineers, Reliability Specialists, Boiler Plant Construction Managers, Consulting Engineers, Design Engineers, Insurance Company Inspectors, Operation, Maintenance, Inspection and Repair Managers, Supervisors and Engineers, Plant Engineers, Senior Boiler Plant Operators, Repairers and Installers, Key instrumentation personnel involved in valve maintenance, Senior management and staff responsible for valve and actuator selection, Mechanical and electrical staff that come into contact with valves, Process control engineers requiring a high plant availability, often affected by valves, Designers, industrial engineers and staff responsible for plant safety, personnel with a vested interest in applications that require or utilize valves

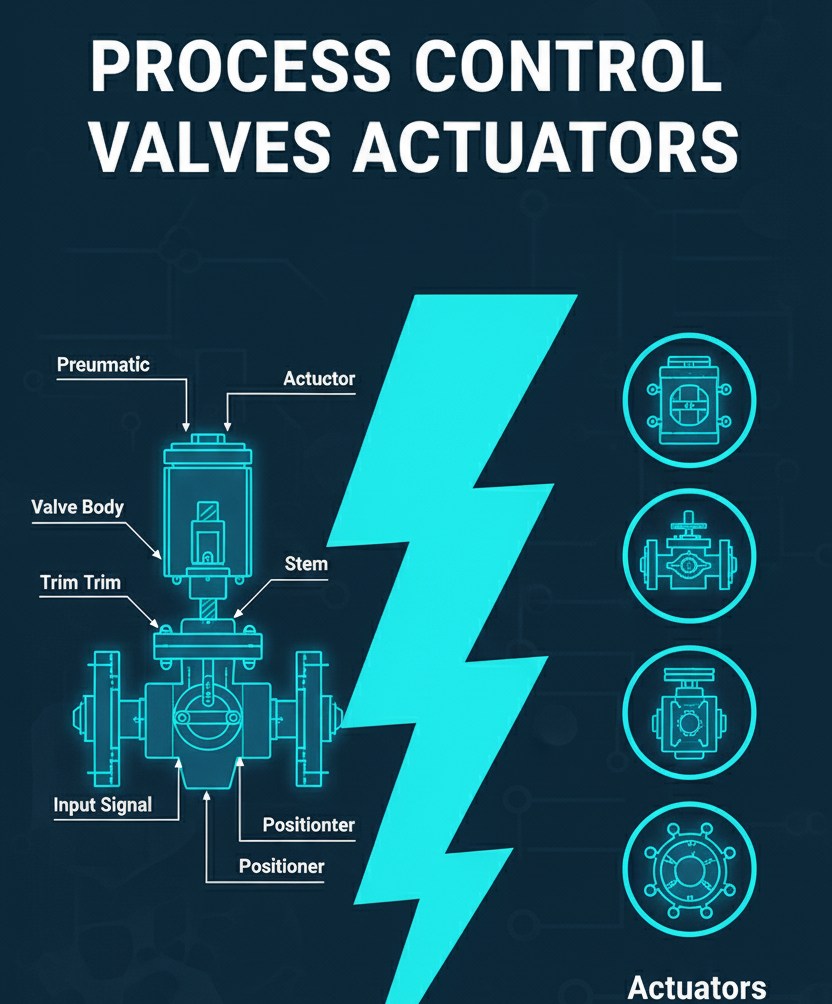

Valve Principals, Purposes, Types, Control Signals and Flow Conditions

Valve in P&IDs, Leakage, Valve Characteristics and Valve Size Calculations

Valve Software, Actuators, Positioners, Cavitation & Noise Control & SIS

3-term Controllers and Loop-Tuning for Processes Containing Control Valves

Using Valves in Cascade, Ratio, Dead-Time Dominant, Non-Linear and PLC-Controlled Processes

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| ME135-02 | 14-06-2026 | Muscat | USD 5450 | |

| ME135-03 | 21-09-2026 | Kuala-Lumpur | USD 5950 | |

| ME135-04 | 25-10-2026 | Cairo | USD 5450 |

In most of oil and gas industries, petrochemical refineries, chemical, food industries the control valve play the most important part in controlling fluid flow and safety of process.

This training course has been designed to take all plant employees (regardless of their background knowledge), and build them up to be versatile and proficient in the use and operation of the various ...

Extensive course materials provided contained useful information about valves/sizing and selection both theoretical and practical. You will gain a practical understanding of control valves, actuators, ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info