By the end of this training course, participants should be able to:

This training course would primarily be aimed at people within the Instrumentation, Electrical, Mechanical, Process disciplines, who are actively involved in the utilization of valves (control or shut-off) and actuators, as well as those people who have the additional responsibility of sizing the valves, and making a decision on the composition and make-up of the valve.

It would also be of great value to those individuals who either have a keen interest in the field, or who have to manage the people working on the various valves and actuators. (In this respect, one could think in terms of Process Control Engineers, Electrical Engineers, Mechanical Engineers, Industrial Engineers, Designers and the like.).

Day One

Practical – Understanding how valves operate, linear vs rotary, and single-action

Practical – Why is it important to achieve stability, when making use of a control valve? Can this stability be demonstrated?

Practical – Calculate a pressure drop that can be experienced

Practical – Converting from mA to percentage

Practical – Converting from percentage to mA

Practical – Working with voltage signals, that range from negative to positive

Practical – Dealing with, and understanding resolution, as can be expected, when sending a signal to a control valve

Practical – Reynolds number calculations

Practical – Do an assortment of pressure conversions, either using tables, or else provided software

Practical – Dealing with cavitation and flashing in a real-world scenario

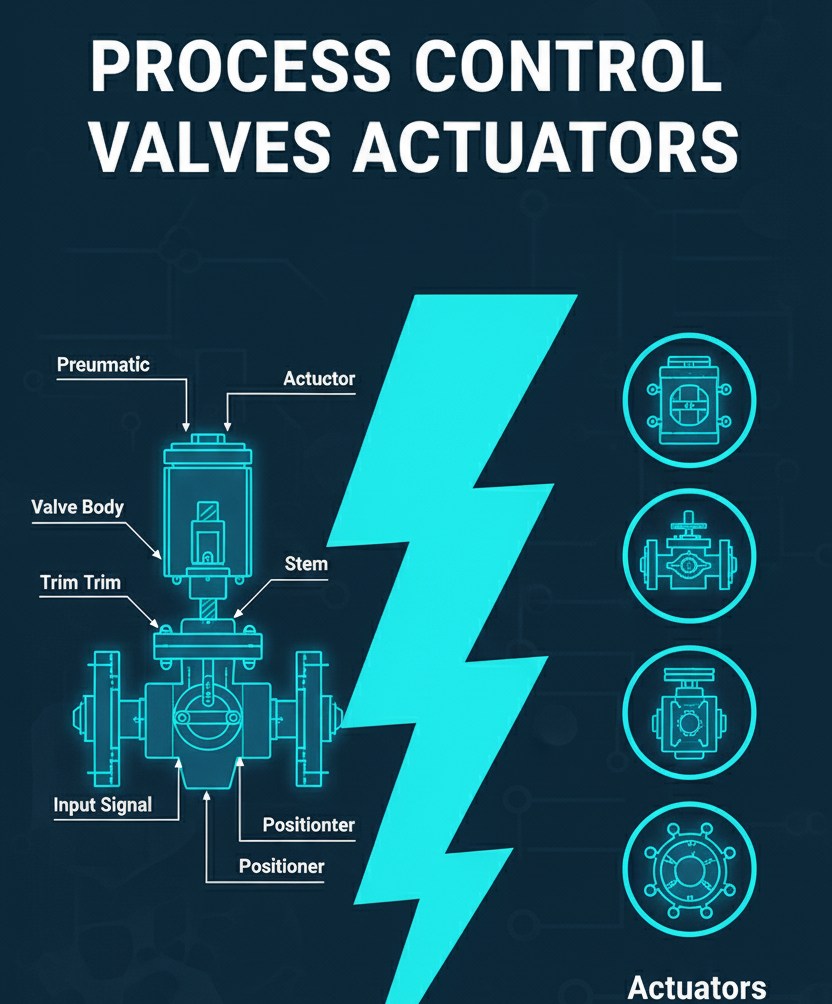

Practical – Labelling of a control valve, from a diagram

Practical – Demonstrate how a valve can be utilised in an application, where there is combined feed forward and feedback control

Practical – Understanding the pressure drops that can be experienced, in pipelines that will contain control valves

Practical – Determining how long a tank will take to empty, should you need to fully open a control valve

Day Two

Practical – Choose the best valve to use, from a table, given specific criteria

Practical – Choose the best valve to use, from a flow chart-type diagram, given specific criteria

Practical – Convert signals from current, to their respective pressure equivalents

Practical – Interpret a P&ID diagram, than contains a control valve

Practical – Design a P&ID diagram, for a loop containing a control valve, using specific criteria that has been provided

Practical – Perform the amount of leakage that can be expected, based on criteria that has been provided

Practical – Understanding the equal percentage characteristics of a control valve

Practical – Understanding the linear characteristics of a control valve

Practical – Choosing the right characteristic, for various control scenarios and strategies that can be encountered

Practical – Visually see how the inherent characteristics can be altered, into installed characteristics, when a valve is installed in the field

Practical – Do all of the calculations, to come up with a control valve, that can be used in a specific application

Day Three

Practical – Making use of computer software, to size a control valve for a liquid application

Practical – Making use of computer software, to size a control valve for a gas application

Practical – How anti-reset windup can be a useful tool, with control valve applications. Delegates will work through a simulator, explaining this out in meticulous detail

Practical – Understanding what a valve positioner does, and how it will affect the operation of a control valve

Practical – Dealing with the issue of noise (as presented in a signal to the control valve), as well as the effects of a sticky valve, and how to counteract this

Practical – Making use of a table, choose the best material to use on a control valve

Practical – Making use of a table, evaluate the various corrosive effects that you may encounter, whilst using control vales

Practical – Making use of a table, evaluate whether your valve is going to be subject to noise / other damage, as a result of cavitation

Practical – Understanding the AUTO / MANUAL aspects of a controller, which will operate on a loop that has a control valve

Practical – The size of a control valve can cause significant changes to the Gain of the Process. This exercise calculates the Gain of a Process, for a specific control valve

Practical – Understanding the effects of Dead Time, on a control valve, and determining what this Dead Time is

Day Four

Practical – Choose the appropriate action that will be required, given a number of scenarios that the delegates will encounter

Practical – Experimenting with the P settings of a controller, understanding what the advantages and disadvantages are, and becoming fully comfortable with how changes will influence the operation of the control valve

Practical – Experimenting with the I settings of a controller, understanding what the advantages and disadvantages are, and becoming fully comfortable with how changes will influence the operation of the control valve

Practical – Experiment with a process, which has both adjustable P and I settings, and how this will affect the operation of a control valve

Practical – Experimenting with the D settings of a controller, understanding what the advantages and disadvantages are, and becoming fully comfortable with how changes will influence the operation of the control valve

Practical – Using the Ziegler-Nichols open-loop tuning methodology

Practical – Using the Ziegler-Nichols closed-loop tuning methodology

Practical – Making use of a Trial and error methodology, in the closed loop strategy

Practical – Making use of a Trial and error methodology, in the open loop strategy

Day Five

Practical – Experimenting with a control valve, that has been placed inside a cascade loop

Practical – Experimenting with a control valve, that has been placed inside a ratio-control loop

Practical – Coming up with a practical, useable solution, when excessive dead time is present in a loop that contains a control valve

Practical – Making use of a PLC simulator, get a control valve to work, using ON / OFF strategies

Practical – Demonstrate the PID blocks, used on a PLC, to control a control valve out in the field

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| IE110-02 | 19-04-2026 | Amman | USD 5450 | |

| IE110-03 | 20-09-2026 | Cairo | USD 5450 | |

| IE110-05 | 22-11-2026 | Manama | USD 5450 |

In most of oil and gas industries, petrochemical refineries, chemical, food industries the control valve play the most important part in controlling fluid flow and safety of process.

Extensive course materials provided contained useful information about valves/sizing and selection both theoretical and practical. You will gain a practical understanding of control valves, actuators, ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info