At the end of this seminar participants will have: * An understanding of different parameters affecting the operation of valves * The ability to select the right valve for the particular application * The ability to perform the necessary calculation for valve sizing * An understanding of the problems associated with valves like flashing, slamming and water hammer * The ability to perform troubleshooting of systems involving valves * The ability to decide on the right maintenance plan concerning different types of valves

Engineers and technicians of mechanical, electrical and chemical engineering will benefit largely from this seminar. Maintenance, operation, and people R and D department are recommended to attend this course.

Day 1

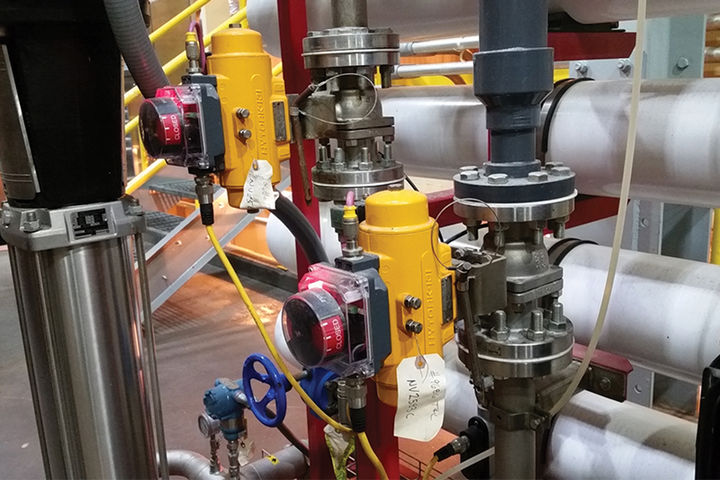

Basics of the Valve Technology

Valves Technology

Types of Valves

Valves Characteristics

Day 2

Manual vs. Automatic Valves

Manual Valves

Functions of Manual Valves

Methods of Regulation

Valve and Connections

Valves Rating

Valves Seating

Check Valves

Applications

Check Valves Operation

Selection of Check Valves

Day 3

Relief and Safety Valves: Function and Operation

Relief and Safety Valves

Valve Loading

Safety Valves

Operation of Rupture Discs

Day 4

Valves Troubleshooting

Valves Problem, and Troubleshooting

High Pressure Drop

Flashing vs. Cavitation

Flow Choking

High Velocities

Surge Protection

Check Valve Slamming

Noise Problems

Clean Air Standards

Life Loading

Packing for Fugitive-emission Control

Troubleshooting and Control Valves

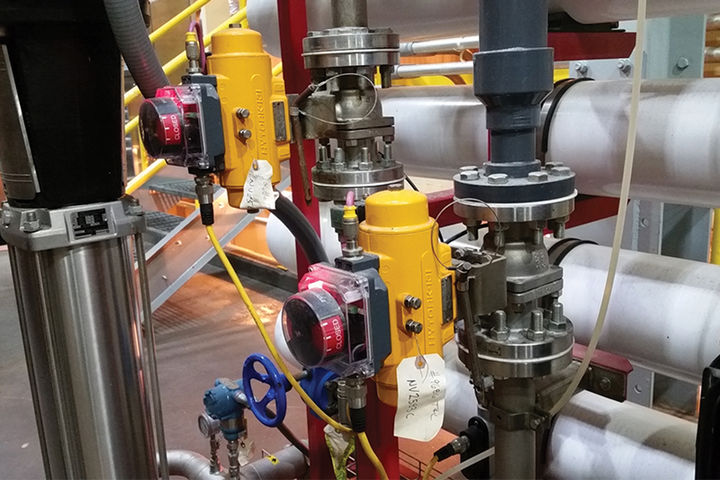

Control Valves and Actuators

Control Valves Types

Linear Valve Features

Rotary Valve Features

Actuation Systems

Actuator Performance

Valve Positioner

Operation of Positioners

Day 5

Valve Sizing and Selection

Valve-sizing Criteria for Manual Valves

Valve-sizing criteria for Check Valves

Valve-sizing Criteria for Throttling Valves

Incipient and Advanced Cavitation

Terminal Pressure Drop Ratio

Percent of Flashing

Pressure Recovery Coefficient

Valve Sizing & Selection Procedure

Selecting a Valve Type

Different Valves Characteristics

Examples

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| ME155-02 | 18-05-2026 | Rome | USD 6950 | |

| ME155-03 | 16-08-2026 | Dubai | USD 5450 | |

| ME155-04 | 08-11-2026 | Amman | USD 5450 |

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info