With this in mind, this course is designed to give both the new and experienced user some insight to problems that valve designers and manufacturing facilities encounter in the real world. The course covers

Mechanical Engineers, Under Development Engineers Supervisors and Technicians.

User, distributor, sales engineers or buyer of this equipment will also benefit & understand much of the design & manufacturing principles that dictates faster delivery of safer quality product.

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

Day 1- Basics of the Valve Technology

Valves Technology

Day 2 - Manual versus Automatic Valves

Manual Valves

Check Valves

Day 3 - Relief and Safety Valves: Function and Operation

Relief and Safety Valves

Rupture Valves

Day 4 - Valves Troubleshooting

Valves Problems, and Troubleshooting

Day 5

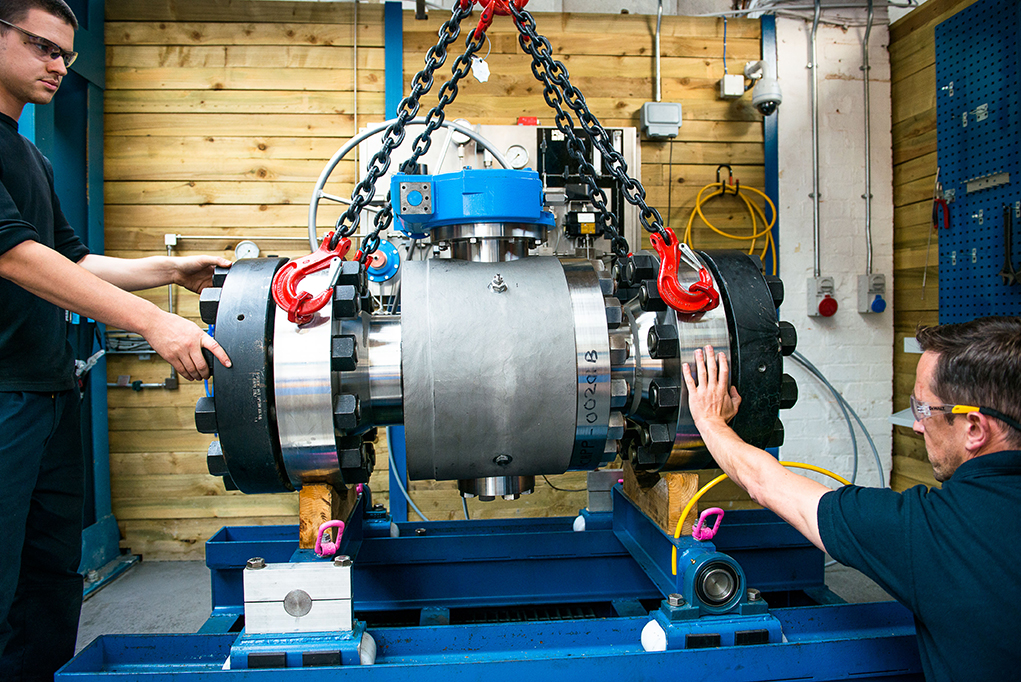

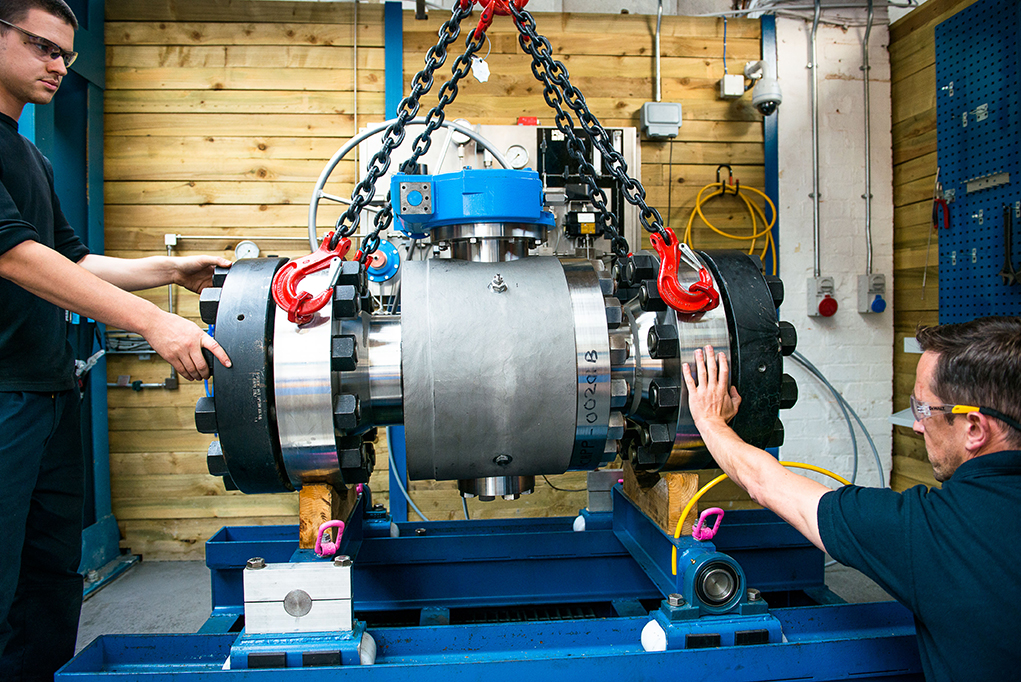

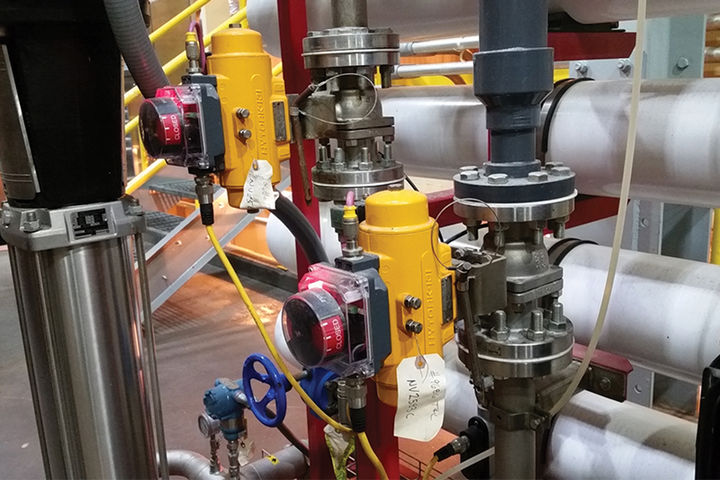

Valve Testing & Repair Facilities

Area of Testing:

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI165-02 | 31-05-2026 | Cairo | USD 5450 | |

| MI165-03 | 23-08-2026 | Muscat | USD 5450 | |

| MI165-04 | 07-12-2026 | Istanbul | USD 5950 |

Power plant and other petrochemical industries do deal with different types of valves. All piping systems are fitted with valves for controlling purposes or safety requirements. Understanding the func ...

Within the boiler, piping and pressure vessel industry, control and safety relief are of most essential importance. Pressure relief valves are the last line of defense against catastrophic failure or ...

The overall purpose of this course is to provide engineers and senior technicians in their relevant fields with the applied knowledge that enables them to efficiently select, maintain or repair differ ...

The overall purpose of this course is to provide engineers and senior technicians in their relevant fields with the applied knowledge that enables them to efficiently select, maintain or repair differ ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info