By the end of this course delegates will be able to:

Maintenance, Mechanical Engineers, Foremen, Supervisors and Technicians, Production Supervisors and Engineers who require an understanding of the Fitness for Service standard, Design and System Engineers, Inspectors, Project and Maintenance Engineers who are personally responsible for the reliable design, operation, maintenance and repair of equipment, systems, tanks, vessels, piping and pipelines

Foundations of Fitness for Service Assessment

The Assessment

Mechanical Integrity and Fitness for Service

Thickness and Stress equations for Assessment

Techniques

Brittle Fracture

Pitting and Corrosion

General Metal Loss

Local Metal Loss

Pitting Corrosion

Blisters and Local Damage

Hydrogen Blisters

Weld Misalignment and Shell Distortions

Cracks and Crack Like Flaws

Creep and Fire

Creep

Fire Damage

Software Review

Overview and Wrap Up

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI133-01 | 16-03-2026 | Rome | USD 6950 | |

| MI133-02 | 14-06-2026 | Amman | USD 5450 | |

| MI133-03 | 06-09-2026 | Dubai | USD 5450 | |

| MI133-04 | 22-11-2026 | Manama | USD 5450 |

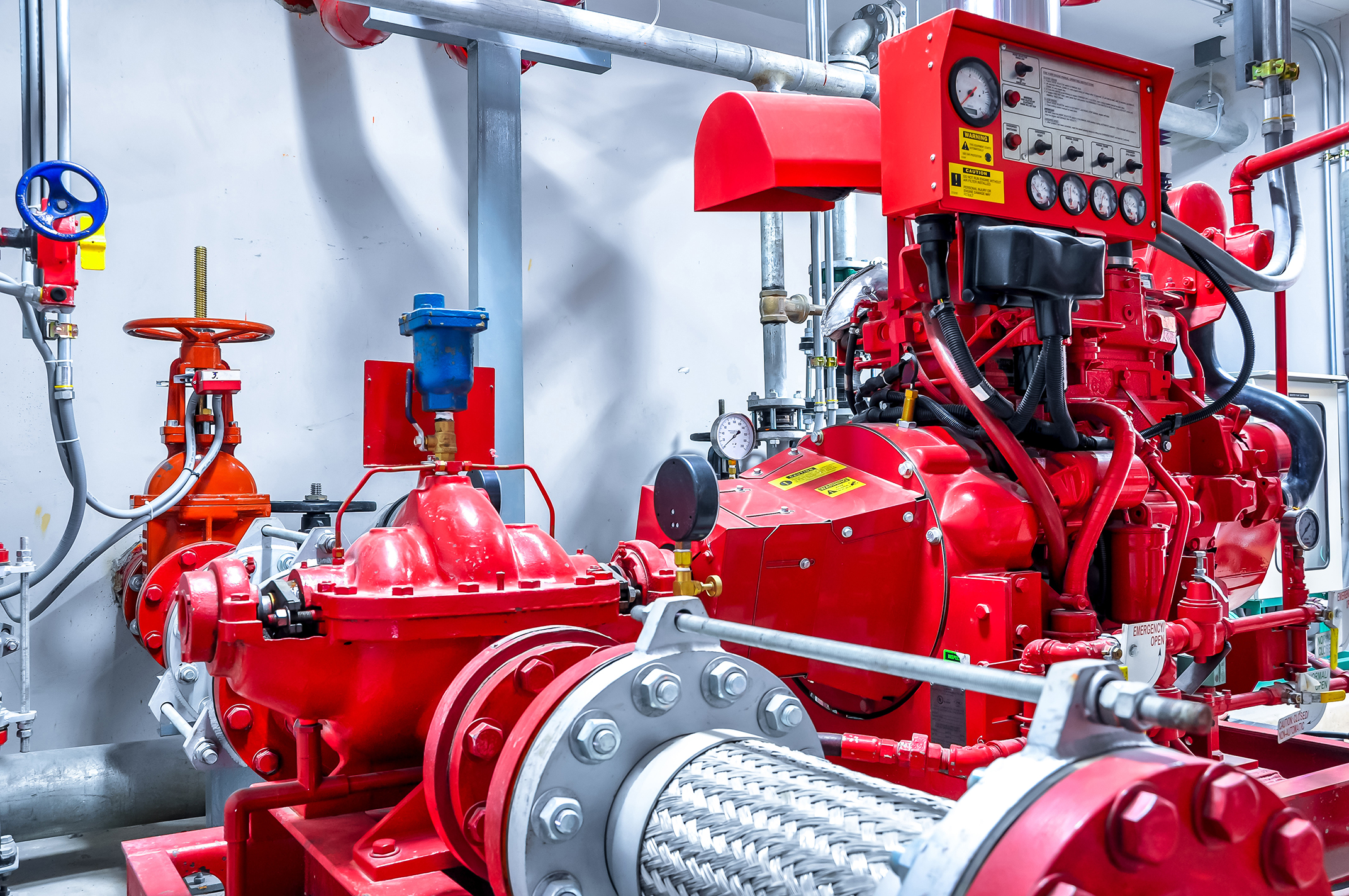

The course will cover topics concerning different types of industrial valves, the control valves and the safety relief valves. Hydraulic pumps, the dynamic and the positive displacement types will be ...

Fitness-For-Service (FFS) assessments are quantitative engineering evaluations that are performed to demonstrate the structural integrity of an in-service component that may contain a flaw or damage. ...

.jpg)

The American Petroleum Institute (API) conducts training classes that can help the candidates understand and use the techniques Fitness-For-Service Assessments of pressurized equipment including press ...

Introduce a team of fresh Mechanical Graduates, with different backgrounds, to various static equipments used in oil & Gas industry; particularly an overview of Block, PFD and P&ID presentation of equ ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info