By the end of this course delegates will be able to:

Maintenance, Mechanical Engineers, Foremen, Supervisors and Technicians, Production Supervisors and Engineers who require an understanding of the Fitness for Service standard, Design and System Engineers, Inspectors, Project and Maintenance Engineers who are personally responsible for the reliable design, operation, maintenance and repair of equipment, systems, tanks, vessels, piping and pipelines, Heads of Maintenance and Operation, Chemical Engineers, Equipment Specialists, Technical Engineers, Operation Engineers, Planning Engineers, Engineers involved with control and safety valves and pumps of different types

PART1: Valves

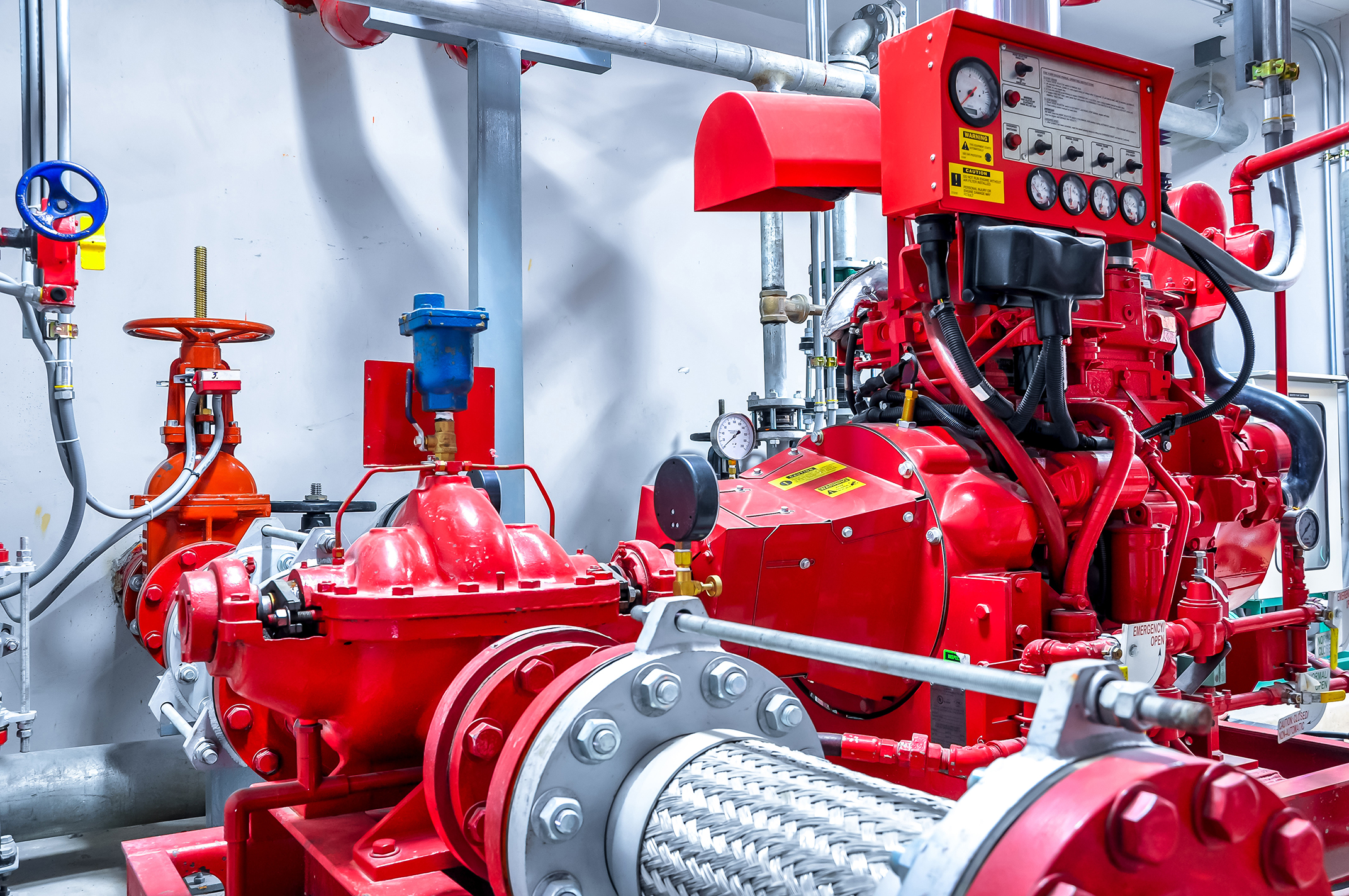

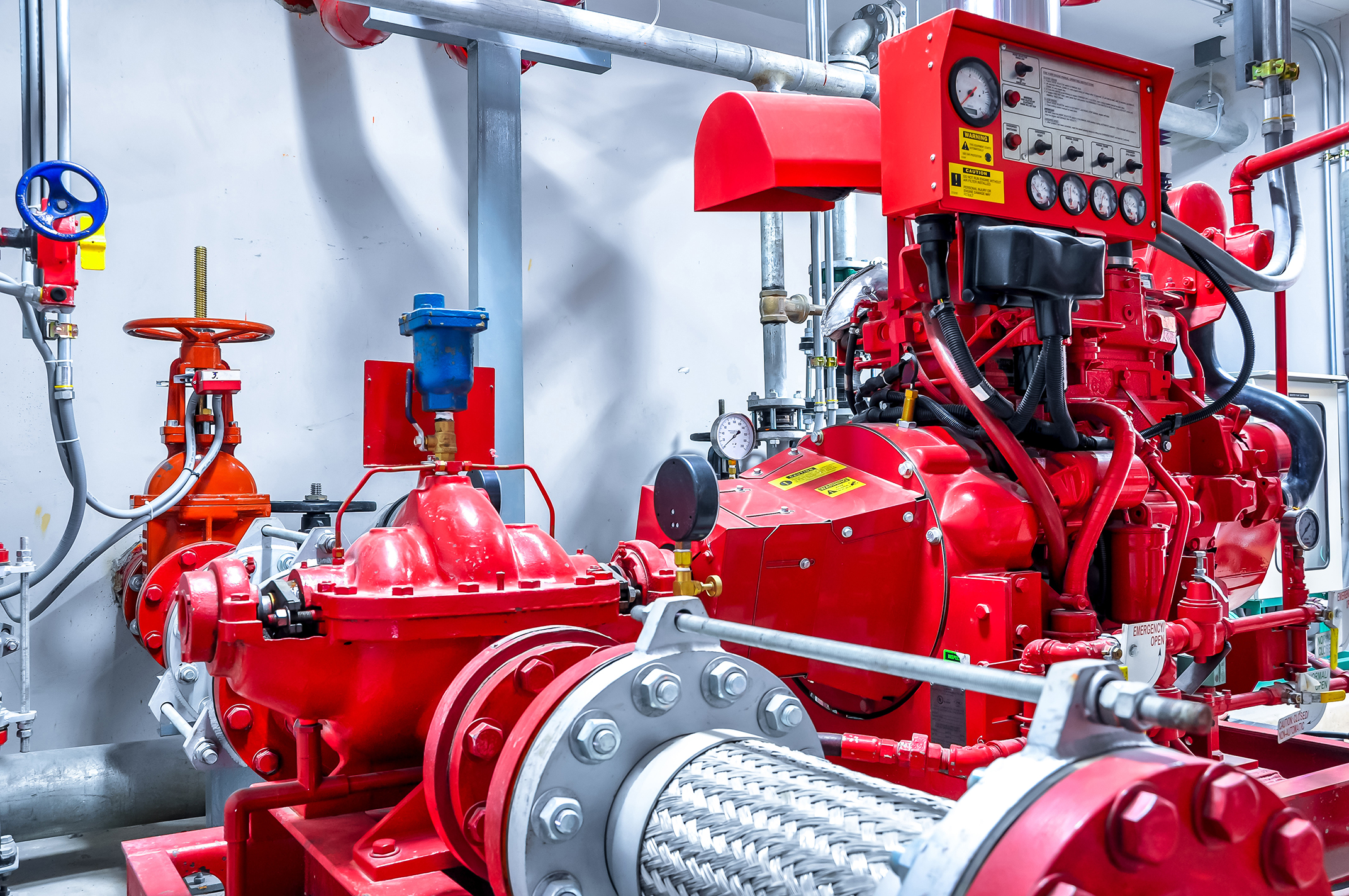

PART2: Pumps

PART3: Foundations of Fitness-For-Service Assessment

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI213-01 | 09-02-2026 | Amsterdam | USD 6950 | |

| MI213-02 | 12-04-2026 | Cairo | USD 5450 | |

| MI213-03 | 26-07-2026 | Doha | USD 5450 | |

| MI213-04 | 15-11-2026 | Dubai | USD 5450 |

.jpg)

Based on the rules for pressure vessel design and construction, this course is a comprehensive introduction to the requirements of Section VIII, Division 1 including background, organization, design, ...

.jpg)

This comprehensive course covers the 2007 Edition of the ASME Code, Section VIII: Division 2. With this Edition, this Code was totally re-written and updated to the latest technology. Some of the desi ...

This course provides an overview of code organization, editions and addenda. The candidates will learn how to prepare and submit an inquiry to the Code Committee for Code Interpretation, Code Cases or ...

Introduce a team of fresh Mechanical Graduates, with different backgrounds, to various static equipments used in oil & Gas industry; particularly an overview of Block, PFD and P&ID presentation of equ ...

This course explains all fundamental principles of fitness for service, their practical application through case histories, and a step by step evaluation process for each type of degradation mechanism ...

Fitness-For-Service (FFS) assessments are quantitative engineering evaluations that are performed to demonstrate the structural integrity of an in-service component that may contain a flaw or damage. ...

.jpg)

The American Petroleum Institute (API) conducts training classes that can help the candidates understand and use the techniques Fitness-For-Service Assessments of pressurized equipment including press ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info