This course covers the analytical methods and their applications are explained with numerous case studies. In order to suit the course to participants with or without a FFS background, the course will be delivered such a way that most of technical terms and both code statements and examples will clarify concepts.

Each attendee must bring a Scientic Calculator

Pressure Vessel/ Piping/ Tank design engineers, process engineers, plant operating engineers and managers, Chemical/ mechanical engineers who are involved in integrity assessment of Columns, Vessels, tanks, piping etc. Also recommended for the Design engineers, Inspection persons and maintenance engineers involved in Repair, maintenance and trouble shooting of plant equipments in Refining, Petrochemical and Chemical industries. Individual certification of API 510/ 570/ 653 will be an added advantage to the participants

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| FAC108-02 | 10-05-2026 | Dubai | USD 5450 | |

| FAC108-03 | 27-07-2026 | Istanbul | USD 5950 | |

| FAC108-04 | 19-10-2026 | Kuala-Lumpur | USD 5950 |

.jpg)

The American Petroleum Institute (API) conducts training classes that can help the candidates understand and use the techniques Fitness-For-Service Assessments of pressurized equipment including press ...

This course explains all fundamental principles of fitness for service, their practical application through case histories, and a step by step evaluation process for each type of degradation mechanism ...

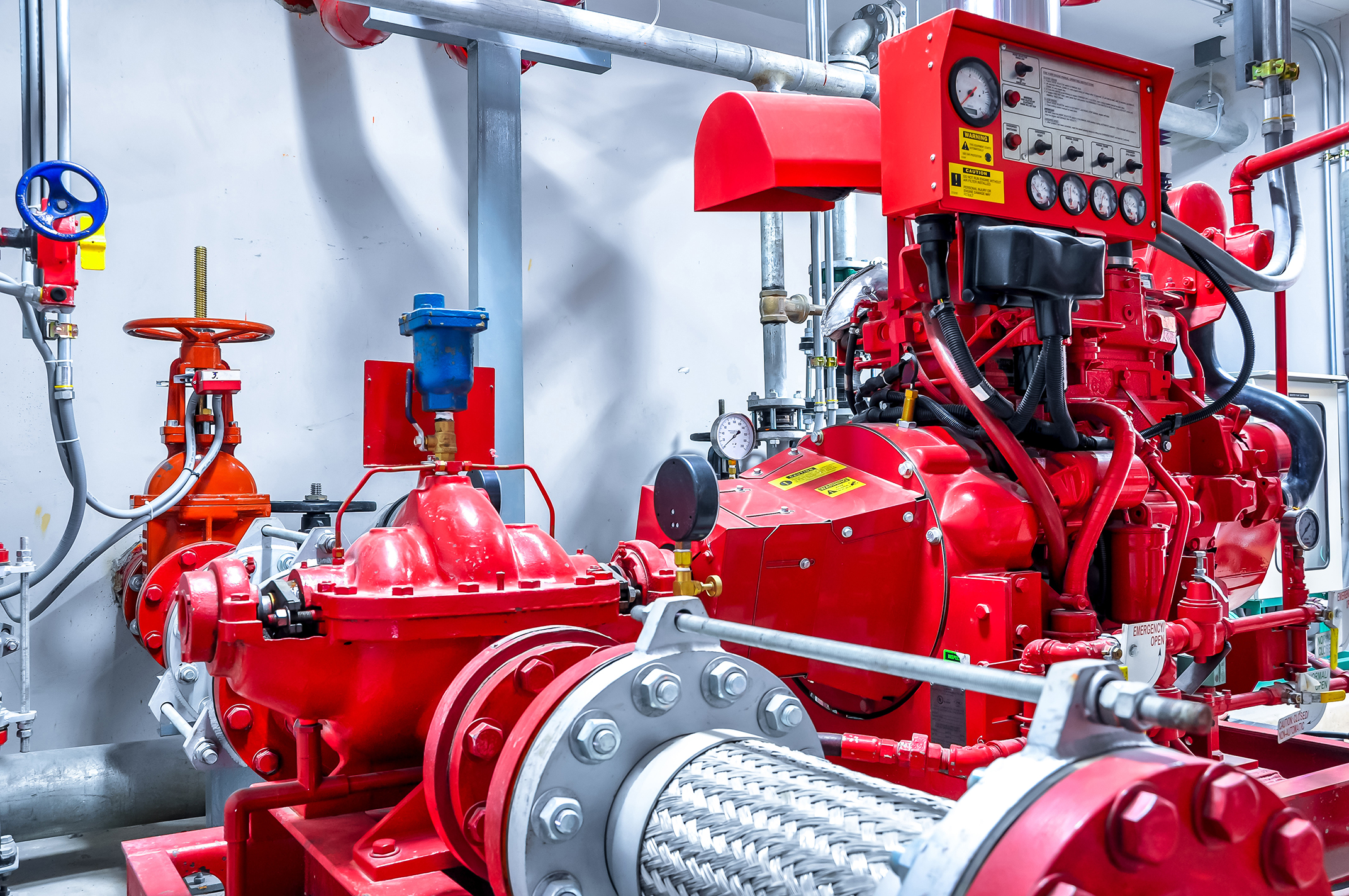

The course will cover topics concerning different types of industrial valves, the control valves and the safety relief valves. Hydraulic pumps, the dynamic and the positive displacement types will be ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info