.jpg)

.jpg)

The highlights include:

By the end of this course delegates will know about:

Inspectors, engineers, and technologists who are involved in performing API 579-1/ASME FFS-1 evaluations, inspecting and analyzing pressure vessels, pressure piping, tanks and pipelines for safe operation when there is a change in service temperature, or where they have been found to be damaged, distorted, cracked, blistered, or experiencing metal loss

Scope of API 579-1/ASME FFS-1

General Assessment Method

Remaining Life Determination

Brittle Fracture Resistance

Metal Loss Evaluation

HIC and SOHIC Evaluation

Evaluating Geometric Irregularities

Evaluation of Cracks and Crack-like Flaws

Problem Solving Session

Creep Damage Assessment

Heat and Fire Damage Evaluation

Lamination Evaluation

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| FAC124-02 | 22-06-2026 | Kuala-Lumpur | USD 5950 | |

| FAC124-03 | 03-08-2026 | Istanbul | USD 5950 | |

| FAC124-04 | 06-12-2026 | Muscat | USD 5450 |

Fitness-For-Service (FFS) assessments are quantitative engineering evaluations that are performed to demonstrate the structural integrity of an in-service component that may contain a flaw or damage. ...

This course explains all fundamental principles of fitness for service, their practical application through case histories, and a step by step evaluation process for each type of degradation mechanism ...

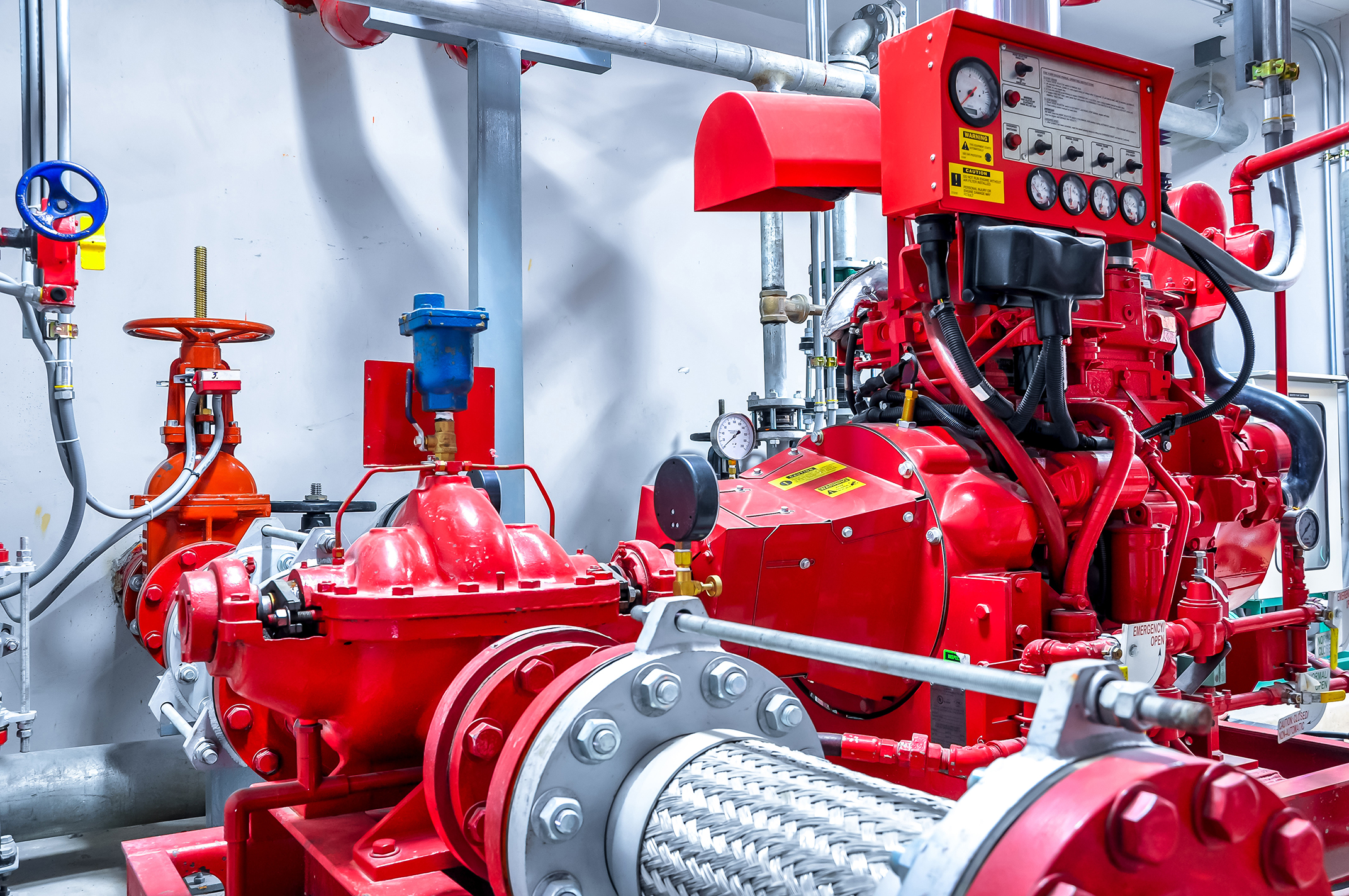

The course will cover topics concerning different types of industrial valves, the control valves and the safety relief valves. Hydraulic pumps, the dynamic and the positive displacement types will be ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info