The effectiveness of maintenance practice has not improved significantly in many organizations in spite of the implementation of powerful computerized management systems. Measuring, comparing and improving maintenance practice underpins the success of the whole business process.

Participants attending the program will:

Identify maintenance best practice key elements for taking action on them, starting with foundations and building up to best practice that will deliver maximum business benefits

Delegates should represent a wide range of personnel in the organization who are involved in, or dependent on, effective maintenance management.

These should include:

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

An Overview of Maintenance Practice and Benchmarking

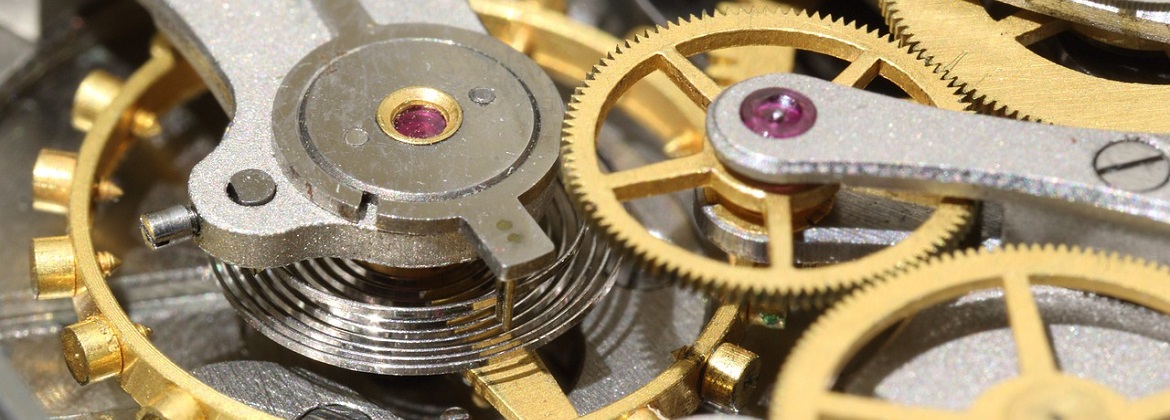

Introduction to Maintenance (Asset) Management

The Concept of Best and Worst Practice

Performance Measures and Improvement

Performance Measure and Benchmarking

The Overall Equipment Effectiveness as a Source of Best Practice in Maintenance

Total Productive Maintenance

Benchmarking Machines Performance and Failure Analysis

Failure Analysis and Modeling

Modeling Reliability of Systems

Benchmarking through Reliability Centered Maintenance

Condition Based Maintenance

The Condition Based Approach

Vibration Monitoring

How and were to Measure Vibration

Diagnosing Faults Using Vibration

General Purpose CM – Non Destructive Testing - NDT

Best Practice Through Manufacturing and Maintenance Systems

MRP and ERP Systems

Decision Analysis for Optimization of Maintenance Activities

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI166-02 | 30-03-2026 | Istanbul | USD 5950 | |

| MI166-03 | 12-07-2026 | Dubai | USD 5450 | |

| MI166-04 | 13-12-2026 | Kuala-Lumpur | USD 5450 |

• Is your equipment (fixed or mobile) failing before planned replacement? • Are you unable to execute maintenance tasks because spare parts are not available? • Have you made significant investment ...

Major world companies from the process and petrochemical industry have developed their maintenance practices based on the optimization of predictive maintenance management system. This approach works ...

Not all of the plant facilities and equipment require high reliability; economically some components can be allowed to run to failure and a reasonable level of reliability is acceptable for other comp ...

This course is designed to teach the skills of availability engineering as detailed in the Facilities Maintenance Management Competency Map. As an intermediate level course we will use root cause fail ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info