By the end of this course delegates will be able to:

The expert will suggest ideas and theories to the delegates and then encourage them to test out the ideas by the use of:

• Discussion

• exercises

• Case studies & DVDs

• group exercisess

• examples

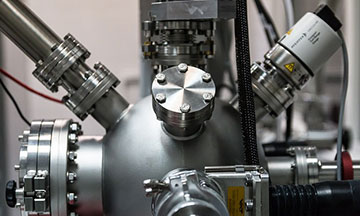

Module 1: Introduction to Gas Compressors

Module 2: Compressor Components and Operation

Module 3: Key Operating Parameters and Controls:

Module 4: Compressor Performance

Module 5: Abnormal Condition and Troubleshooting:

Module 6: Monitoring and Performance Evaluation

Module 7: Maintenance Strategies

Module 8: Troubleshooting Common Issues

Module 9: Compressor condition monitoring system

Module 10: Practical Applications and Case Studies

Group discussions and knowledge sharing

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI139-02 | 14-06-2026 | Manama | USD 5450 | |

| MI139-03 | 06-09-2026 | Dubai | USD 5450 | |

| MI139-04 | 13-12-2026 | Amman | USD 5450 |

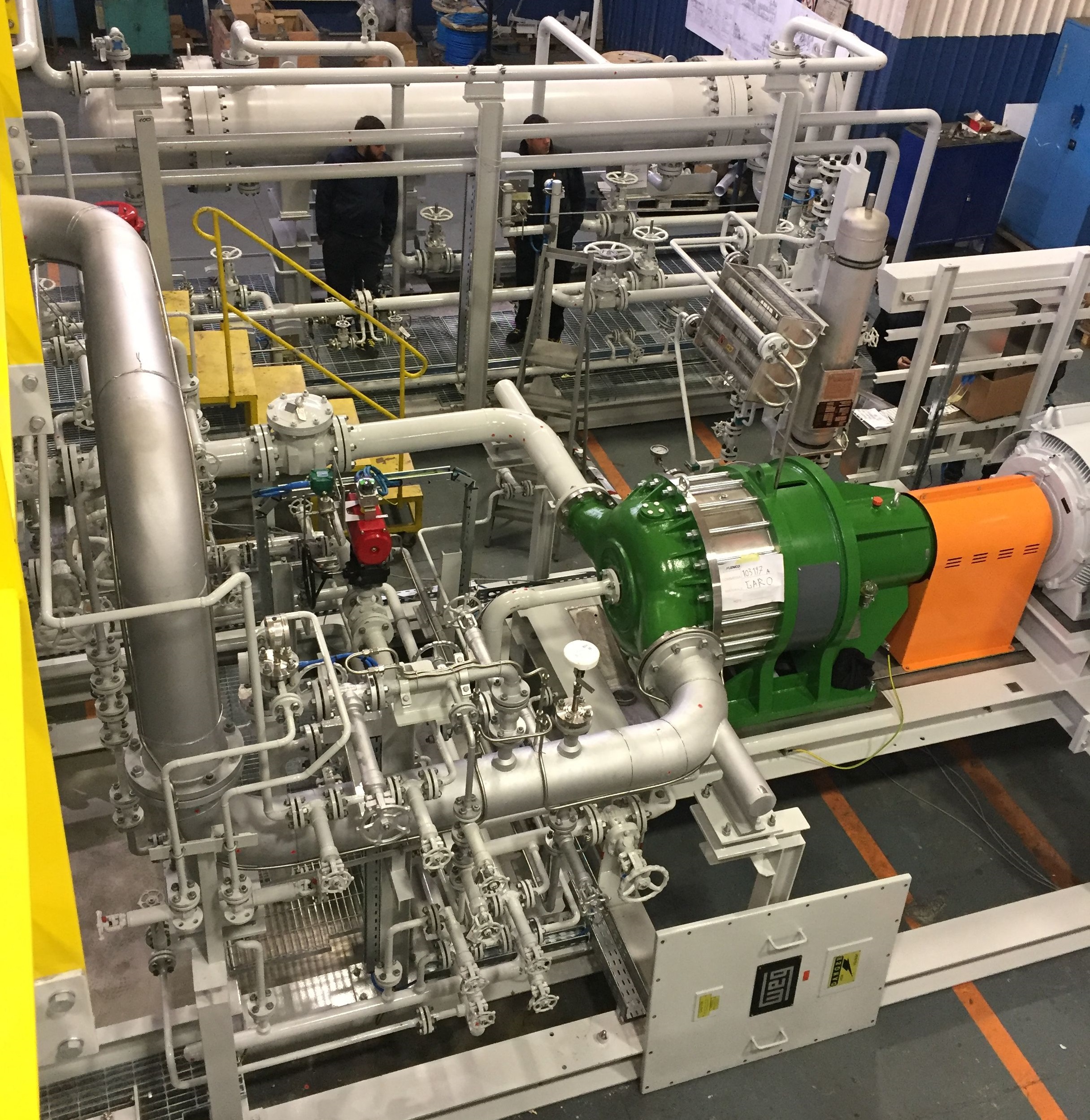

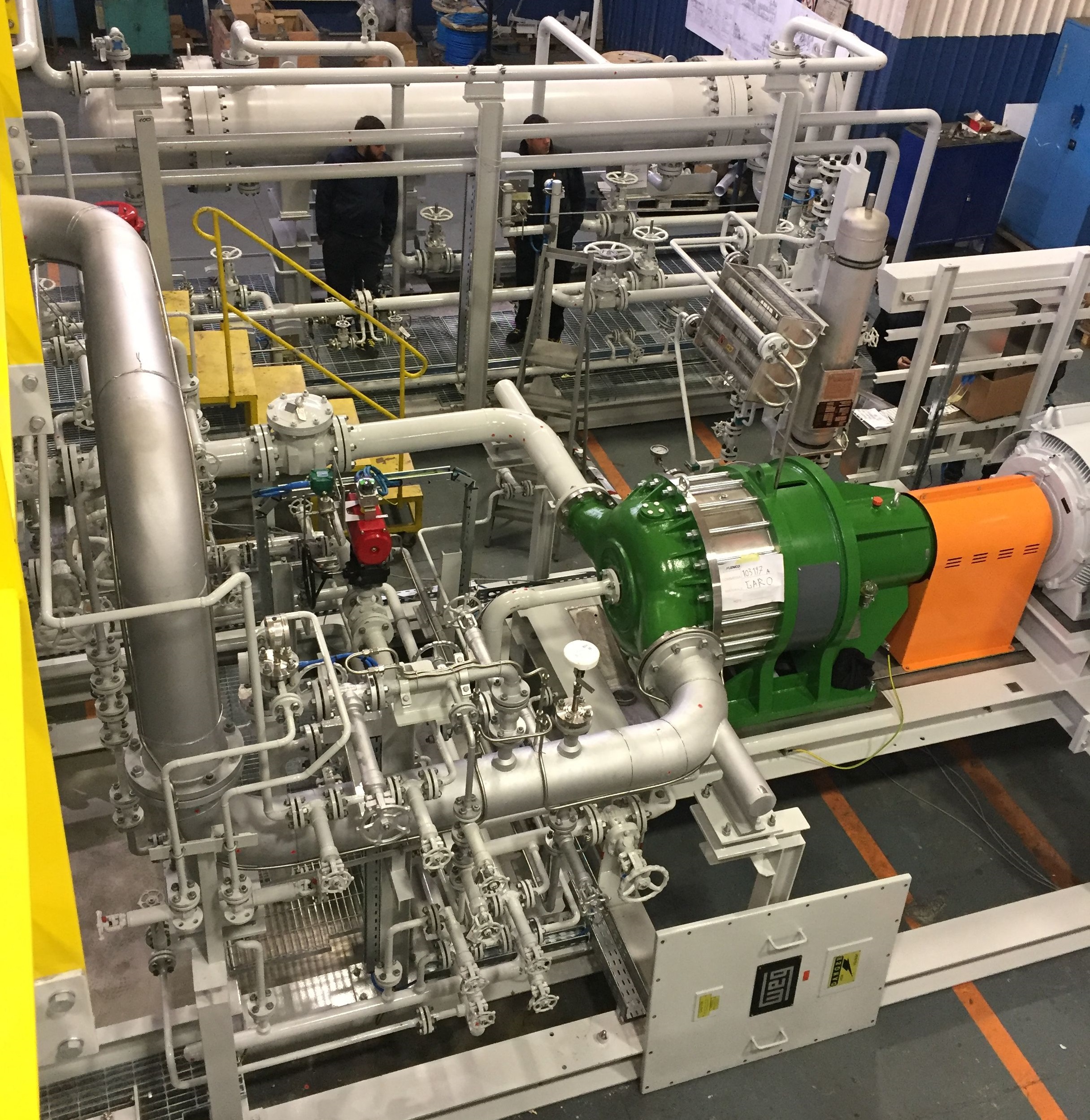

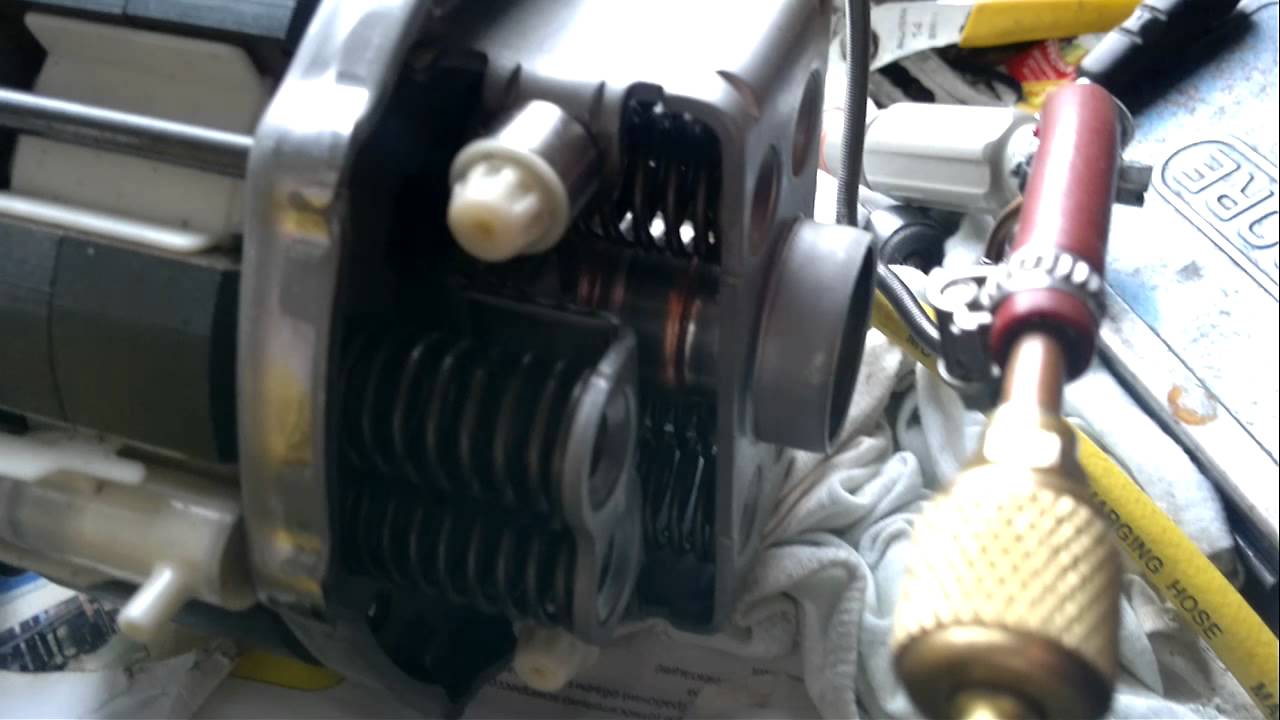

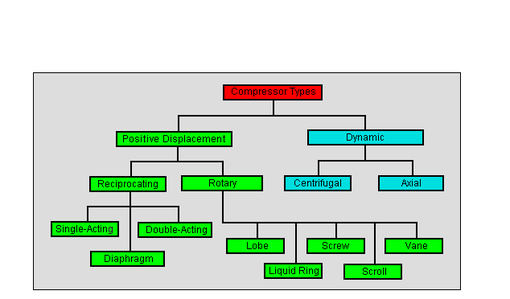

This programme provides a comprehensive understanding of the various types of reciprocating, rotary, and dynamic compressors. This includes trunk piston, sliding crosshead piston, diaphragm, rotary s ...

The course will introduce delegates to the various types of compressors and associated terminology. Centrifugal and positive-displacement compressors, packing, mechanical seals and sealing systems, be ...

Upon completion of this course, participants will have gained a thorough understanding of the various centrifugal (i.e. turbo) and reciprocating compressor configurations available to virtually every ...

Centrifugal Compressors a play a very essential role in many petrochemical and industrial plants. Centrifugal compressors in general runs at very high speeds, exposed to high temperature. The compress ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info