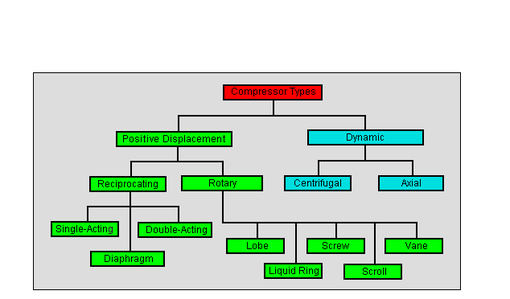

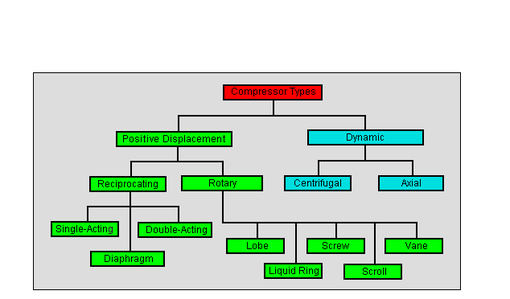

Centrifugal and Reciprocating Compressors of several types, which have widely varying configurations and applications, are used extensively in the process industries. These compressors represent a significant part of the capital and operating costs of most plants, so that optimizing their selection is of major economic importance.

The course is devoted to design features, efficiencies, operating characteristics, reliability and maintenance implications of centrifugal compressors.

This course will cover the operating principles of centrifugal compressors, specifications, their design, thermodynamics, effects of efficiency on operating costs, energy usage, effect on plant costs, special materials of construction, selection, troubleshooting and maintenance.

The course will also cover plant run-length extension surveys, organizing for successful turnarounds and ongoing reliability improvement, and preventive vs. predictive maintenance strategy decisions.

The course will provide the participant with a basic, as well as advanced, centrifugal and reciprocating compressor technology inventory required to successfully select, apply, troubleshoot and maintain compression equipment. Throughout the course, participants will have ample opportunity to have equipment-related questions answered by the Course Director.

This application and equipment course is intended to be of direct use by persons in staff positions (e.g., Senior Technicians, Operators, Supervisors, Superintendents) and corporate engineering, plant planning and design, systems design, equipment selection and evaluation, and equipment maintenance areas. It will be of value to equipment and systems specialists in engineering contractor firms. This course should also be valuable to managerial and supervisory individuals responsible for operations and maintenance functions. The industries most directly involved with the subject matter are those producing chemicals, petrochemicals, petroleum products, natural gases, manufacturing gases, steel and other metals, and plants requiring process refrigeration.

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include:

Module 1

Module 2

Module 3

Module 4

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| ME161-02 | 21-06-2026 | Dubai | USD 5450 | |

| ME161-03 | 13-09-2026 | Cape Town | USD 6950 | |

| ME161-04 | 18-10-2026 | Manama | USD 5450 |

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info