This training course will feature:

By the end of this course delegates will be able to:

Reliability Engineers, Maintenance Managers, Engineers & Planners, Reliability and Maintenance Engineers, Facilities and Utilities Managers, Design Engineers, Top Level Maintenance Technicians, OE Champions, Predictive and Preventive Maintenance, Technicians & Supervisors, Planners, Maintenance Supervisors, Crafts and Tradesmen, Operations Supervisors, Process Engineers, Inspectors and Inspection Supervisors, Equipment Engineers Team Leaders and Professionals in Maintenance, Engineering and Production, Maintenance managers, reliability and maintenance Engineers, Production Managers, Plant Engineers, Design Engineers, Reliability Engineers and Technicians, Operators, Safety Engineers, Risk Engineers, Safety Engineers and anyone who is involved in Reliability Engineering strategies or methodologies to include design engineers for capital projects engineers, Foreman and Technicians, Mechanical, Electrical and Operational Personnel, Personnel designated as Planners, Key leaders from each maintenance craft, Key operations personnel, Technical professionals responsible for maintenance and repair of equipment, Professionals involved in inspection and maintenance and repair, professionals involved in asset & maintenance management auditing, Quality & Compliance Managers, Lead Auditors & Audit Team Members, Process Controllers, Maintenance Supervisors, Maintenance Planners, Predictive Maintenance Technicians & Supervisors, Materials Management Managers and Supervisors, Service Company Representatives, Asset owners & Asset Managers

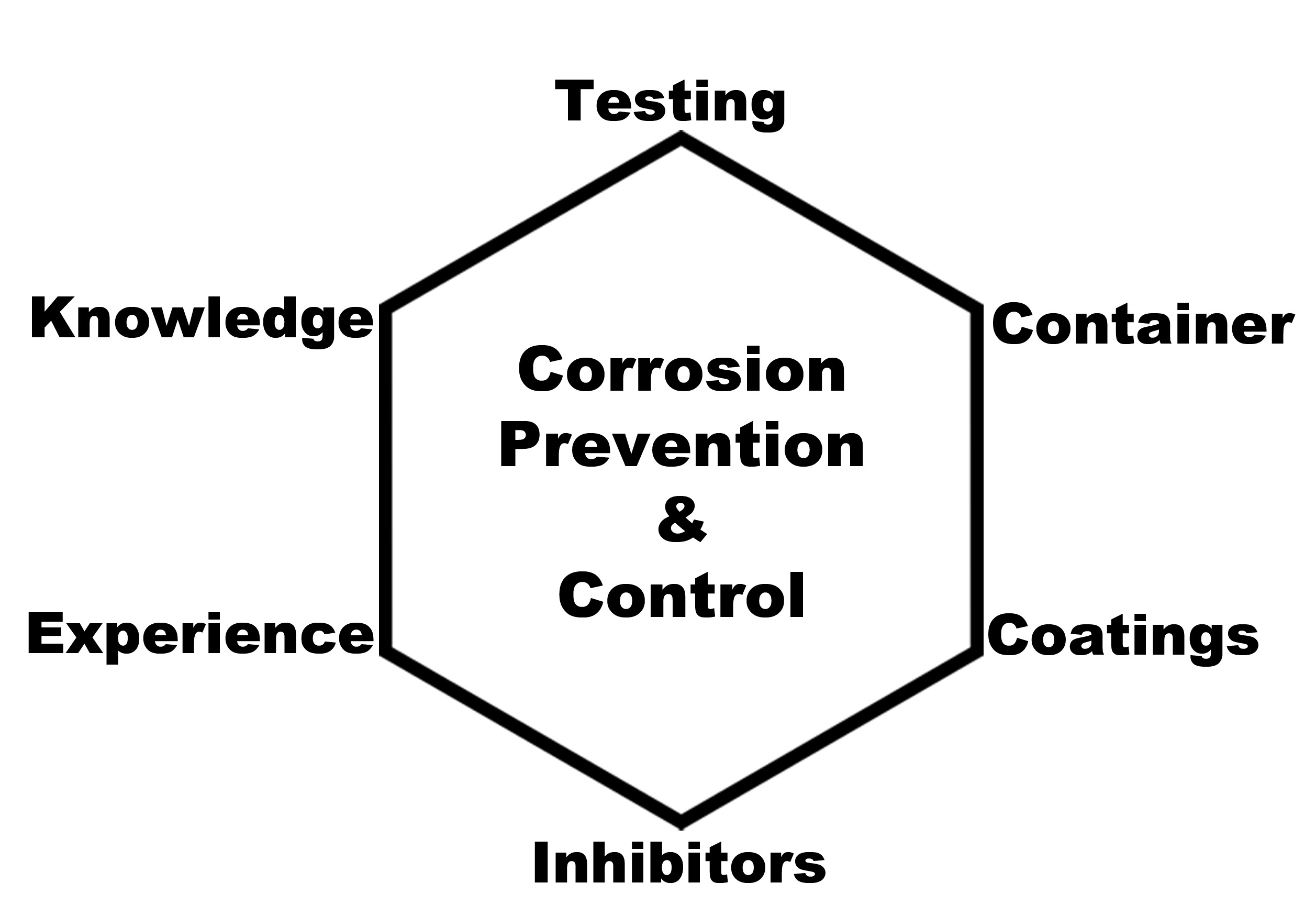

Fundamentals of Corrosion Principles

Types of Corrosion in the Refinery Industry, Related to Oil, Gas and Water

Materials of Construction for Refinery Applications

Corrosion Control, Protection and Monitoring

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI123-02 | 10-05-2026 | Riyadh | USD 5450 | |

| MI123-03 | 07-09-2026 | Istanbul | USD 5950 | |

| MI123-04 | 15-11-2026 | Manama | USD 5450 |

This corrosion course covers fundamental aspects of corrosion control and its prevention. The course will enable beginners to establish a solid foundation in corrosion before moving on to advanced top ...

This basic corrosion course covers fundamental aspects of corrosion control and its prevention. The course will enable beginners to establish a solid foundation in corrosion before moving on to advanc ...

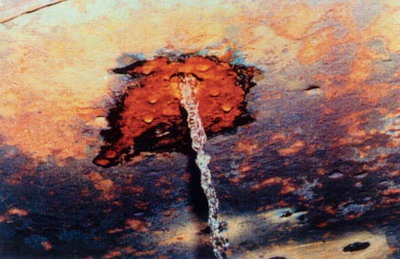

The effect of corrosion in the oil industry leads to the failure of parts. This failure results in shutting down the plant to clean the facility. The annual cost of corrosion to the oil and gas indust ...

The production of gas and oil is often accompanied by water, either from the formation, from condensation, or from water injected as lift assist. Acid gases, such as hydrogen sulfide (H2S) and carbon ...

Corrosion problems have always presented a severe challenge to oil and gas producing operations. Operators plan for long periods of continuous production with maintenance scheduled for the prescribed ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info