By the end of this course delegates will be able to:

Corrosion Control Engineers & Personnel, Process Engineers, Metallurgists, Inspection Personnel, Mechanical Engineers, Material Selection Personnel, Plant Contractors, Operations Engineers, Team Leaders & Supervisors, Maintenance Supervisors, Senior Plant Supervisors, Mechanical Engineers, Corrosion Control & Monitoring Systems Personnel, Oil and Gas Production Facilities Personnel, Chemists, Chemical Engineers, Technicians and Supervisors, New Petroleum Engineers, Asset Management Personnel, Design & Construction Engineers, Team Leaders & Coordinators, Construction Coordinators, Maintenance Engineers, Technologists, Maintenance Team Leaders & Engineers, Personnel who are / will be responsible for detecting, inspecting, monitoring, controlling corrosion in oil and gas piping, pipelines used in production operations and Personnel responsible for metallurgy, corrosion or the prevention of failures in plant and equipment.

Corrosion Basics

Dissolved Gas Removal for Corrosion Control

Corrosion Inhibitors

Metallurgy & Materials Selection for Oil and Gas Facilities

Introduction to Cathodic Protection

Coatings, Linings and Non-Metallic's

Corrosion Monitoring

Microbiologically Influenced Corrosion

Inspection Practices

Review of API 570-Piping Inspection Code (Inspection, Repair, Alteration and, Rerating of In-service Piping Systems)

API 574: Inspection Practices for Piping System Components

NACE MR0175: Sulphide Stress Cracking Resistant Metallic Materials for Oilfield Equipment

NACE MR0103: Materials Resistant to Sulphide Stress Cracking in Corrosive Petroleum Refining

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI122-02 | 11-05-2026 | Kuala-Lumpur | USD 5950 | |

| MI122-03 | 09-08-2026 | Manama | USD 5450 | |

| MI122-04 | 23-11-2026 | Istanbul | USD 5950 |

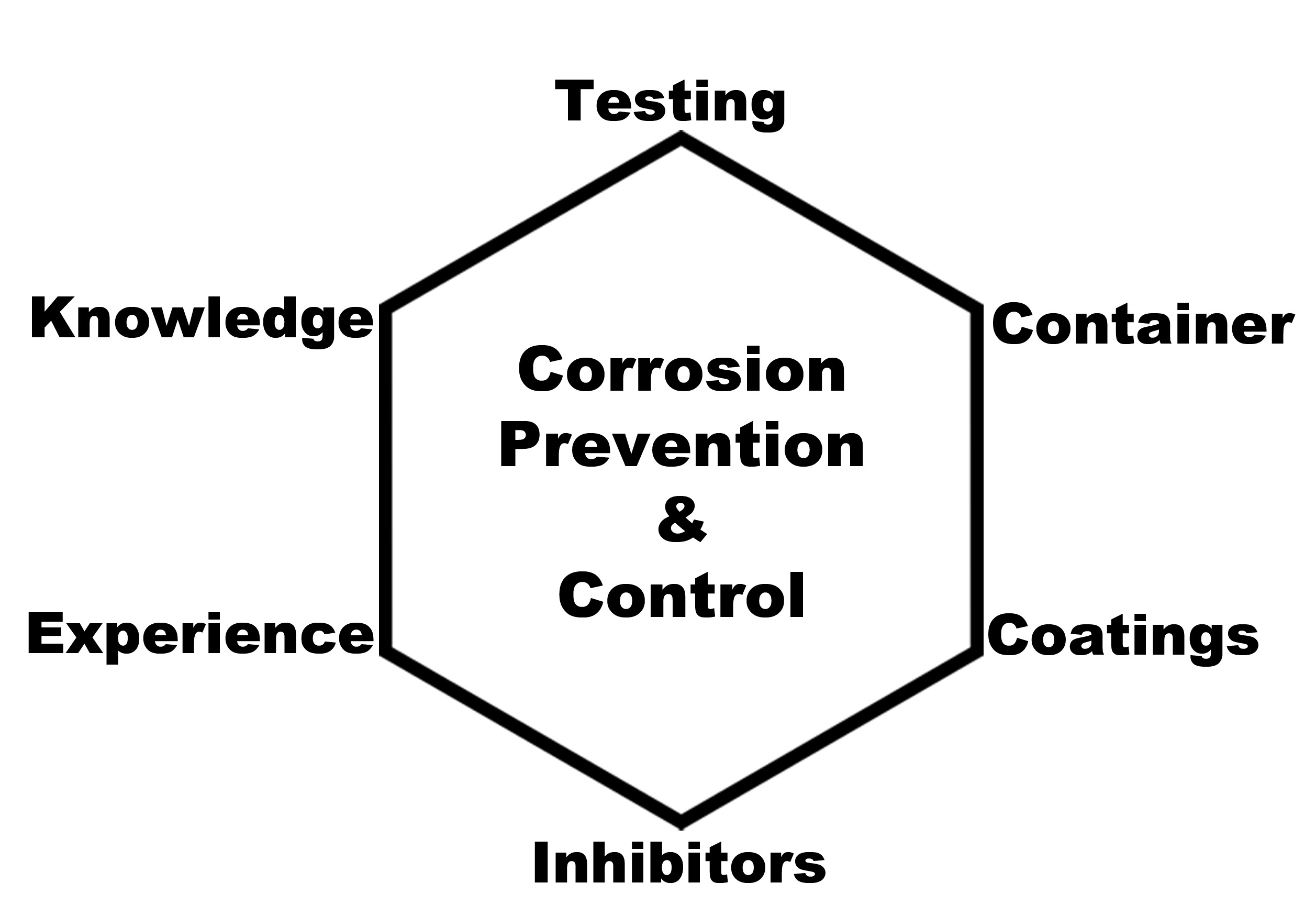

This corrosion course covers fundamental aspects of corrosion control and its prevention. The course will enable beginners to establish a solid foundation in corrosion before moving on to advanced top ...

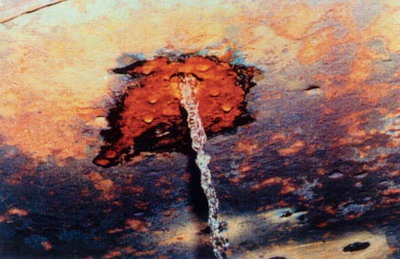

The production of gas and oil is often accompanied by water, either from the formation, from condensation, or from water injected as lift assist. Acid gases, such as hydrogen sulfide (H2S) and carbon ...

The effect of corrosion in the oil industry leads to the failure of parts. This failure results in shutting down the plant to clean the facility. The annual cost of corrosion to the oil and gas indust ...

This basic corrosion course covers fundamental aspects of corrosion control and its prevention. The course will enable beginners to establish a solid foundation in corrosion before moving on to advanc ...

The production of gas and oil is often accompanied by water and acid gases, such as (H2S) and (CO2) are often present in produced fluids. These increase the corrosivity of the process, which can signi ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info