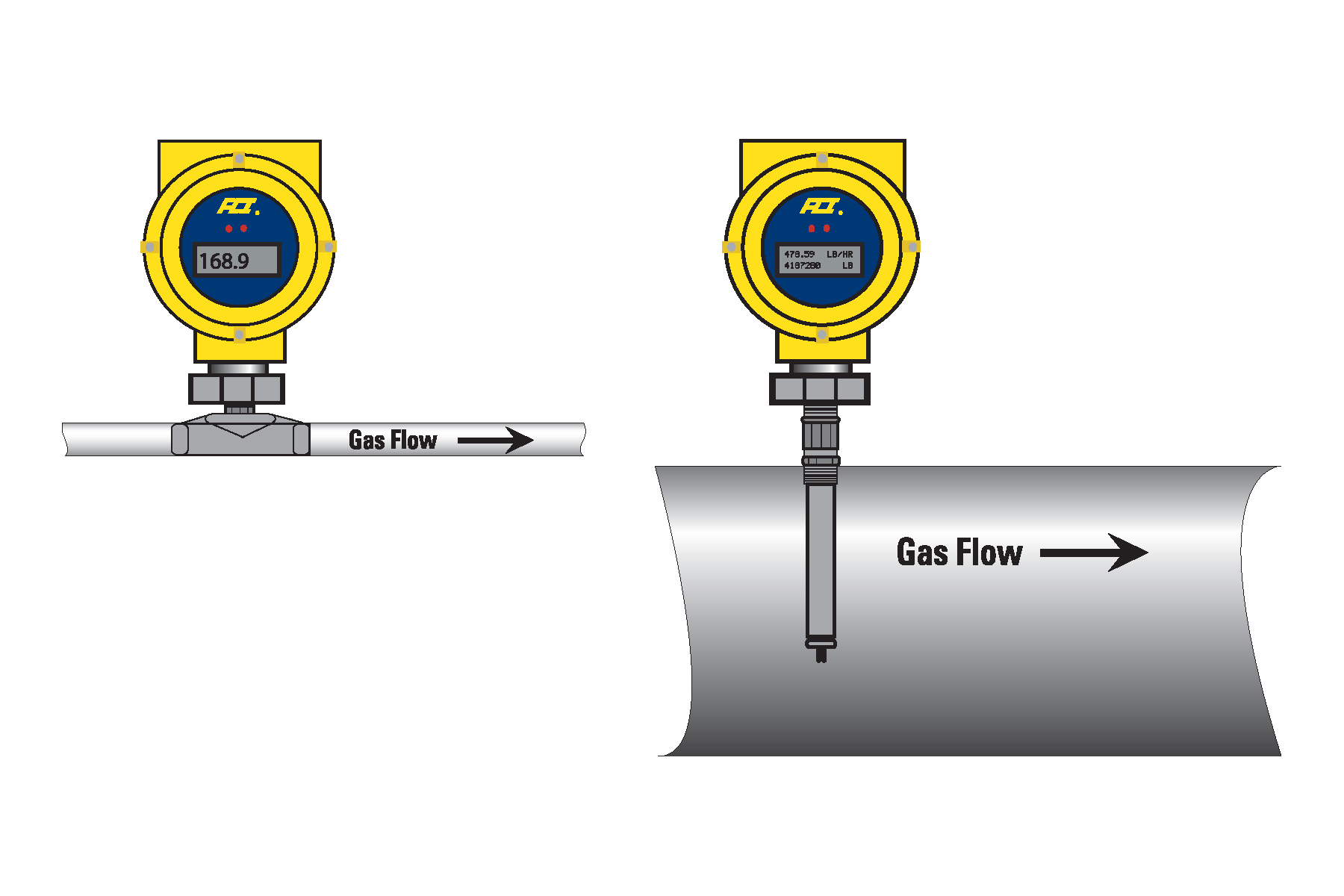

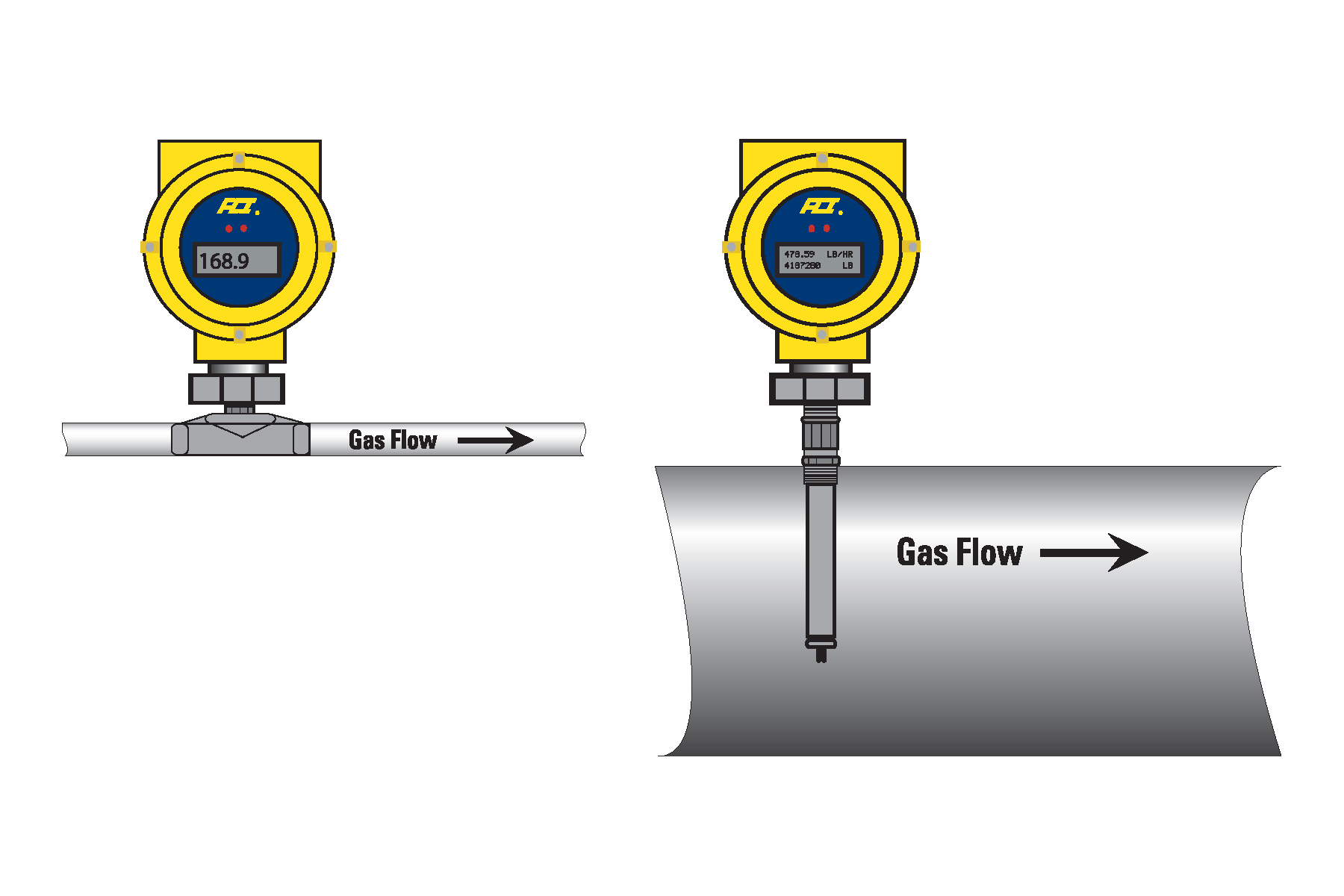

The course comprises of the basic flow measurement theory of gases in pipes and conduits. The effects of pressure and temperature on flow meters and on flow measurements are explained in detail, and an insight into fluid dynamic terminology is provided, e.g. Reynolds numbers.

Particular emphasis will be given to differential pressure generating flow meters; orifice plates, Pitot tubes and Venturi meters, Coriolis, as well as other types of flow meter. The advantages and disadvantages of each type will be fully explained as well as the important interaction between flow measurement and gas sampling.

This training course has been specially developed for personnel that are required to work with and or are involved in selecting, maintaining, troubleshooting and calibrating gas flow measurement systems. It will also be of great benefit to personnel who are involved in sampling, analysis & custody transfer operations that require specific knowledge to conduct measurements & calculations in flow systems.

This training course is suitable to a wide range of professionals but will greatly benefit:

This course will utilise a variety of proven adult learning techniques to ensure maximum understanding, comprehension and retention of the information presented. This includes interactive sessions with questions, discussions and problem solving under supervision along with syndicate exercises. It will be conducted as an interactive workshop that encourages participants to share their own experiences and apply the programme material to real-life situations.

The course will be reinforced by a learning mix that includes, lecture style presentation, short videos, open discussion, case studies, simulations and syndicate exercises.

Day One: Introduction to the Physics of Gas Flow

Day Two: Measurement Concepts

Day Three: Metering systems I

Day Four: Metering systems II

Day Five: Custody Transfer Instruments

CDGA attendance certificate will be issued to all attendees completing minimum of 75% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| PE142-02 | 07-06-2026 | Doha | USD 5450 | |

| PE142-03 | 06-09-2026 | Dubai | USD 5450 | |

| PE142-04 | 06-12-2026 | Amman | USD 5450 |

Accurate flow measurement is essential to today's industries, oil & gas operations. Our Fiscal Metering Training Course aims to provide training to facility operators, technicians and engineers, which ...

This 5 day course covers various aspects of flow assurance (i.e. gas hydrate, wax, asphaltene, scale, corrosion, emulsion) with particular emphasis on gas hydrates. In each case the nature of the pro ...

the design, operation, control, and optimization of chemical, physical, and biological processes through the aid of systematic computer-based methods. Process engineering encompasses a vast range of i ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info