Petroleum, production, process, drilling engineers / operators / technicians / managers.

CDGA attendance certificate will be issued to all attendees completing minimum of 75% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| PE143-01 | 30-03-2026 | Istanbul | USD 5950 | |

| PE143-02 | 28-06-2026 | Doha | USD 5450 | |

| PE143-03 | 06-09-2026 | Dubai | USD 5450 | |

| PE143-04 | 20-12-2026 | Amman | USD 5450 |

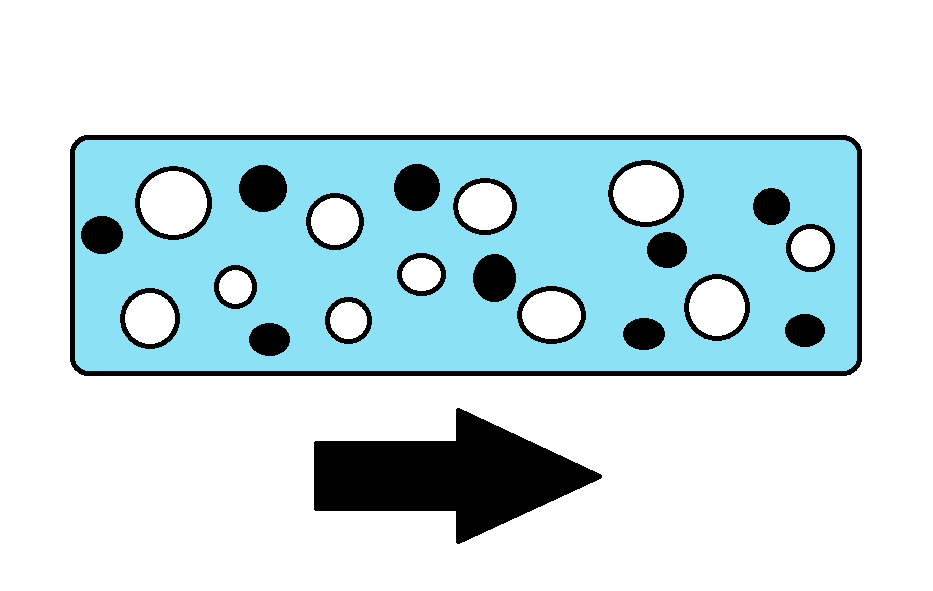

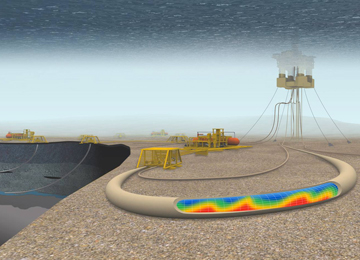

Flow assurance is a relatively new term in oil and gas industry. It refers to ensuring successful and economical flow of hydrocarbon stream from reservoir to the point of sale. Flow assurance is most ...

This course will teach participants about the single phase fluid and how to do the basic calculations of pressure drops. They will also learn how to do pressure drop calculations for multiphase flow, ...

During this five-day course, you will learn how OLGA dynamic multiphase flow simulator is used to understand and solve typical flow assurance challenges. This interactive and practical course include ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info