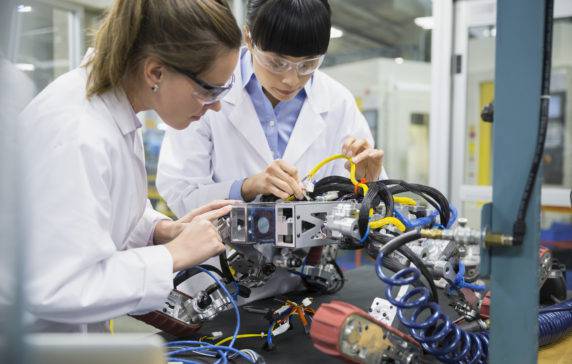

This course is designed to meet the needs of individuals of all disciplines and will also benefit those with a mechanical background seeking to refresh their knowledge.

By the end of this course, delegates will be able to:

Mechanical Engineers, General Supervisors, Consulting Engineers, Design Engineers, Foremen, Supervisors, Technicians, Maintenance Personnel, Engineers of all disciplines, Supervisors, Team Leaders and Professionals in Maintenance, Engineering and Production Managers, Maintenance Personnel, Heads of Maintenance and Operation, Chemical Engineers, Equipment Specialists, Technical Engineers, Operation Engineers, Planning Engineers, Process Engineers, Reliability Specialists, Boiler Plant Construction Managers, Consulting Engineers, Design Engineers, Insurance Company Inspectors, Operation, Maintenance, Inspection and Repair Managers, Supervisors and Engineers, Plant Engineers, Senior Boiler Plant Operators, Repairers and Installers, Project Engineers and Technologists, Facility Engineers, Consultants, Mechanical Engineers and Technologists, Maintenance and Operation Personnel, Plant/Facility Engineers,Technicians, Maintainers, Operators, Chemical Engineers & Technologists, Process Engineers & Technologists, Project Engineers & Technologists

Introductions to Mechanical Engineering

Regulations Codes and Standards: Engineering Materials

Metal Fabrication Processes

Maintenance & Planning Practices

Torque and Power

Power Transmission

Lubrication

Bearings

Pressure Vessels

Liquid Storage Tanks

Heat Transfer Systems and Equipment

Fired Boilers, Process Heaters and Heat Recovery Equipment

Instrumentation and Control

Fluid Engineering

Industrial Piping

Pumps

Fans and Compressors

HVAC and Refrigeration Systems

Process and Instrument Diagrams

Miscellaneous Mechanical Components

Equipment Reliability

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| ME119-02 | 10-05-2026 | Kuala-Lumpur | USD 5950 | |

| ME119-03 | 23-08-2026 | Riyadh | USD 5450 | |

| ME119-04 | 13-12-2026 | Cairo | USD 5450 |

This course for engineers and piping system designers reviews the key areas associated with the design of piping systems for oil and gas facilities. The course is focused on four areas: codes and stan ...

This course reviews the design of mechanical components for process vessels in oil and gas facilities. The emphasis is on codes and standards sizing calculations and materials selection vessel specifi ...

Mechanical engineering in simple terms deals with any equipment that moves; this is what makes it perhaps the most broad and diverse of engineering disciplines. The mechanical discipline essentially d ...

Heat exchangers are important and expensive pieces of equipment that are used in a wide variety of industries. This course will enable you to improve heat exchanger effectiveness and extend the equipm ...

Process engineering is at the heart of much of the chemical, oil, gas, and petrochemical industries. It requires familiarity not only with chemical engineering principles, but also with many of the ot ...

This five-day foundation level course is for engineers and technicians seeking an in-depth understanding of centrifugal, reciprocating, and screw compressors. This course provides basic knowledge of c ...

This course introduces the basics and fundamental concepts and applications of mechanical engineering. The course starts with an introduction to the basic principles of mechanical drawings such as tol ...

This course will provide a comprehensive review of the various aspects of engineered safety and mechanical integrity in refineries, oil & gas plants and petrochemical plants. Principal emphasis is pl ...

The course is directed to the participants to enable them to unerstand the basic idea of the shell and tube devices and taking care of the new and advanced technology that is available nowadays. The c ...

This training program aims at providing the participants with a comprehensive theoretical and practical knowledge, practical aspects, and enhancing their knowledge and skills for basics of mechanical ...

.jpg)

In this 5-day course, participants will gain a strong technical and practical understanding of mechanical seals and gland packing through the exploration of design features and implications of many se ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info