The main features of the course will be:

By the end of this course delegates will be able to:

Reservoir Engineers, Senior Reservoir Engineers, Well Testers I, Well Testers II, Production Engineers, Petroleum Engineers, Production Supervisors, Geoscientists, Drilling Engineers and other disciplines engineers who want to understand well testing and interpretation techniques to design, analyze report, evaluate results or intelligently participate in the well testing process.

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| DE117-02 | 07-06-2026 | Dubai | USD 5450 | |

| DE117-03 | 16-08-2026 | Muscat | USD 5450 | |

| DE117-04 | 07-12-2026 | Istanbul | USD 5950 |

In this course all surface and subsurface testing tools and operations introduced before will be discussed in more detailed and advanced level. Also, understanding of the safe handling of the produced ...

Downhole Remediation for Mature Oil and Gas Wells is presented from a practical point of view. Discussions include decision processes for selection, design, and application of methods that are support ...

This comprehensive course provides the candidates with a basic understanding of the methods used to: design, conduct and analyze well tests in order to obtain reliable information about well condition ...

Specifications of drill string components, design methods for overload and fatigue including combined loads, calculation of working capacity, specification of inspection programs, and the use of Stand ...

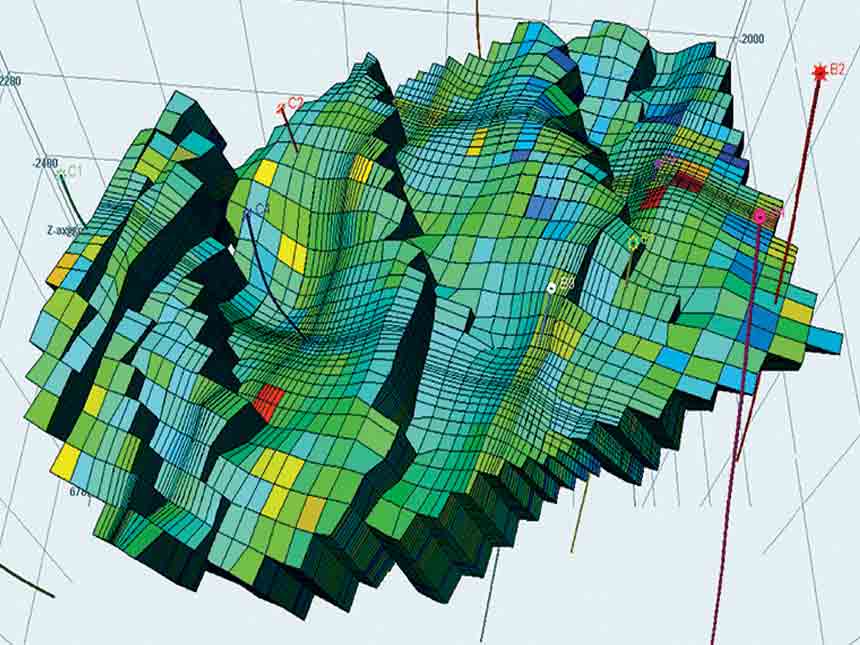

Principles and practice of well test analysis from the perspective of deriving properties of reservoir description. Fundamentals of well testing and integration of well testing with geological descrip ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info