The course covers how this equipment operates and provides guidelines and rules that must be followed for a successful operation. Their basic design, operating characteristics, specification, selection criteria, advanced fault detection techniques, critical components as well as all maintenance issues are covered in detail.

This course is designed to provide a comprehensive understanding of the various types of transformers, rectifiers and inverters, uninterruptible power systems (UPS), circuit breakers, and fuses. Upon the successful completion of this course, participants will be able to specify select, commission, troubleshoot and maintain this distribution equipment for their applications. Further, participants will have enough knowledge to achieve reduced capital, operating and maintenance costs along with increase in efficiency. During the duration of this course, participants will:-

Engineers and Technicians with Electrical Backgrounds from Electrical Power Utilities Companies, Manufactures, Engineering Professional, Petrochemical Companies, and Commercial Buildings are recommended to attend

• Pre-test and pro-test

• Variety of learning methods

• Lectures

• Case studies and self-questionnaires

Testing, Troubleshooting Principles and Commissioning Guide of Electrical Equipment

1. Introduction

1. Basic principles in using a drawing and meter in troubleshooting circuits

2. Checks for circuit continuity with disconnected supply

3. Checks for circuit continuity with live supply

4. Tests and methods

5. Testing devices

6. Testing and Commissioning Methods

7. Testing and Commissioning Procedures.

8. Maintenance of Particular Types of Electrical Equipment

9. Nomo gram for temperature correction

10. Test voltages for Commissioning and Maintenance

11. Recommended insulation values for equipment

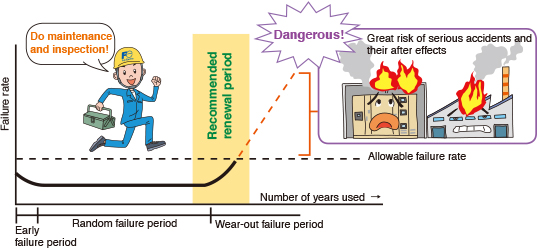

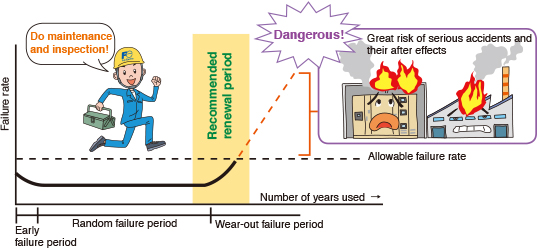

Principles of Maintenance

1. Preventive Maintenance (PM)

o Basics

o Elements

2. Predictive Maintenance(PdM) (Condition-Based Maintenance) (CBM )

o The Basic Concept of Predictive Maintenance

o Benefits of Predictive Maintenance

3. Impact of Maintenance

o Role of maintenance organization

o Types of Maintenance

Maintenance Improvement

Corrective Maintenance

Reactive Maintenance

Condition Monitoring

Scheduled Maintenance

Condition Monitoring For Electrical Equipment

1. Insulation Resistance Monitoring

o Insulation resistance test (IR)

o Components of DC Leakage Current

o Megger test

o Polarization index test

o AC & DC hi-pot test

o Measuring insulation degradation

o Insulation power factor

o On line measuring partial discharge activity for insulation

o PDA Curves

2. On-Line Monitoring of Transformers

o Local Indications

o Thermography

o PDA - Partial Discharge Analysis

o Insulating Oil Properties And Tests

o Test for Dielectric Strength

o Water Content in Oil

o Acidity Test (Neutralization Number)

o Oxidation Inhibitor

o Interfacial Tension Test (IFT)

o Oil Color

o Oil Power Factor Test

o Insulating Oil Dissolved Gas Analysis (DGA)

Earthing Systems

1. Introduction

2. Equipment Earthing

3. System Earthing

• Unearthed systems

• Solid earthing

• Resistance earthing

• Reactance earthing

4. Classification o Supply / Installation System Earthing

5. Earthing Via Neutral Earthing Compensator

• Distribution transformers

• Zig Zag transformers

6. Comparison of Methods (Advantages/Disadvantages)

• Evaluation of earthing methods

7. Testing the earthing electrode Resistance & Earthing grids.

Circuit Breaker Fundamentals, Maintenance, Operation, Testing and Troubleshooting

1. Overview to PU systems

2. Breaking & Making Capacities

3. TRRV

4. Fundamentals of breaking technologies

• Air Circuit Breakers.

• Vacuum Circuit Breaker

• SF6 Circuit breaker

• Oil Circuit Breaker Ratings

• Fuses

• Trip Circuit Supervision

• Circuit-Breaker Control

• Low Voltage Molded Case Current Limiting Circuit Breakers

5. HV Circuit Breakers Maintenance

6. H.V Circuit-Breakers Tests

7. Low voltage Circuit Breaker Maintenance

Transformer Fundamentals, Maintenance, Testing and Troubleshooting

1. Principles of Transformers

• Saturation Curve & Voltage Ratio of Transformers

• Current Ratio & Impedance of Transformers

• Transformer Construction

• Transformer losses and efficiency

• Transformer Cooling & Types

• Transformer Polarity

• Transformer Applications

• Transformer Accessories

• Maintaining Transformers

• K-Factor Transformers

• Dry & Oil types

2. Preventative Maintenance

• Transformer Inspection

• Transformer Liquids

• Dielectric Test

• General Testing

• Other Important Tests

• Transformer Failure

• Disassembly for Inspection

3. Common Transformer Abnormalities

4. Transformer Oil Tests

5. Fault Analysis

UPS, Rectifiers, Inverters and Batteries Fundamentals Maintenance, Testing and Troubleshooting

1. UPS Fundamentals

• Rectifications & Inverters

• Inverters

• Batteries and Battery Charging

• Battery Charging Tests

• Safety During Battery Charging

• Mixing Electrolyte

2. Batteries (Lead acid and alkaline types).

3. Battery discharge test.

4. Troubleshooting Guides.

Power Quality Problems

• Introduction to Power Quality - IEEE 1519.

• Grounding & Bonding.

• Mitigation techniques.

• Sources of harmonics, interharmonics and subharmonics.

• Harmonic Limits IEEE 519-2004.

• Capacitor banks.

• Voltages in the system.

• Harmonic measurements

• Voltage disturbances.

• Understanding harmonics.

• Effects on power system component.

• Calculating harmonic current.

• Harmonic filters.

• Solving problems in actual system.

Safety Policies & Electrical Hazards

• Safety rules

• Authorization levels

• Safety documents

• Hazardous associated with electrical equipments

• Electrical hazards & Shock to human

• Arc Flashing hazards (IEEE 1584)

• Incident energy

• Boundary distances

• Labeling

• PPE

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| EE104-01 | 30-03-2026 | London | USD 6950 | |

| EE104-02 | 07-06-2026 | Dubai | USD 5450 | |

| EE104-03 | 06-09-2026 | Muscat | USD 5450 | |

| EE104-04 | 06-12-2026 | Dubai | USD 5450 |

This course covers the theoretical and practical operation of common electrical equipment and components, as well as provides participants with the necessary knowledge and skills to perform electrical ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info