Participants will gain an understanding of the relationship between voltage and current to work on and troubleshoot electrical systems. The course will also cover Direct Current (DC) and Alternating Current (AC) circuit concepts, transformers' types of uses and their interaction in an electrical circuit, as well as the necessary knowledge to work on and fix motor control circuits. As electrical hazards can result in serious injury to personnel that work on or around electrical equipment, the course will also focus on international safety requirements, including OSHA standards, and best practices. Participants will learn the steps needed for the prevention of electrical injuries.

By the end of this course delegates will be able to:

Electrical Engineers, Electrical Technicians, Electrical Inspectors, Electrical Professionals & Supervisors, Instrumentation and Design Engineers, Maintenance Engineers, Supervisors & Technicians, Energy Management Consultants, Control Engineers & Technicians, Automation & Process Engineers, Chemical & Mechanical Engineers, Consulting Engineers, Field Technicians, Graduate Engineers, Project and Production Managers, Project Engineers, Electronic Technicians, Plant Managers, Process Control Engineers, System Engineers, System Integrators, Testing Engineers & Technicians, Power System Engineers, Power System Technicians, Utility Engineers, Managers & Team Leaders of Engineering Departments, Safety Professionals, Plant Electricians, Facilities Engineers, Operations & Maintenance Engineers, Supervisors & Technicians, Project Engineers, Commissioning & Testing Engineers, Consulting Engineers, Electrical Technologists, Facility & Plant Managers

Electrical Concepts

Electrical Terminology

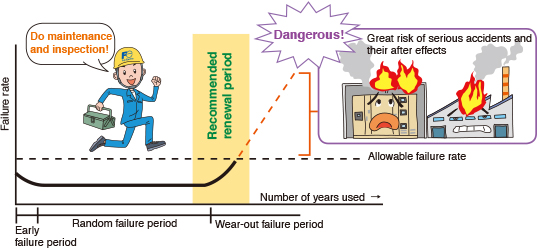

Electrical Components: Operation, Control and Maintenance

Electrical Maintenance Planning

Electrical Hazards & Protective Measures

Hazard Assessment Concerns for Live Electrical Work

CDGA attendance certificate will be issued to all attendees completing a minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| EE103-02 | 10-05-2026 | Doha | USD 5450 | |

| EE103-03 | 10-08-2026 | Kuala-Lumpur | USD 5950 | |

| EE103-04 | 08-11-2026 | Manama | USD 5450 |

This course focuses on equipping participants with the knowledge and skills to implement effective electrical safety techniques in industrial settings. It covers hazard identification, risk mitigation ...

Accurate troubleshooting and subsequent repair of electrical equipment is necessary in today’s sophisticated industrial environments to ensure continued efficient operation and productivity of the equ ...

Maximum efficiency, reliability, and longevity of electrical distribution equipment such as the various types of transformers, rectifiers, inverters, uninterruptible power systems, circuit breakers, f ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info