NOTE: The course maintains a balance between lecture and in-class exercises and between theory and application. A variety of in-class exercise sessions are evenly dispersed throughout the course to emphasize the principles covered. Students are encouraged to put into practice the fault-finding techniques covered during the course

On successful completion of this workshop delegates will be able to:

Designed for both novice and experienced engineers and technicians, this workshop starts at fundamental principles and progresses through basic coding and formatting systems, error detection, and protocols through to advanced fieldbus and device networking concepts.

Throughout the workshop, participants will learn through active participation using exercises, questionnaires, and practical troubleshooting using protocol analysis and covering:

This Training will be highly interactive with opportunities to advance your opinions and ideas and will include:

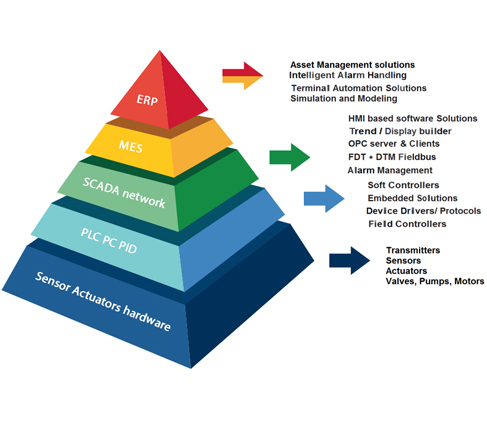

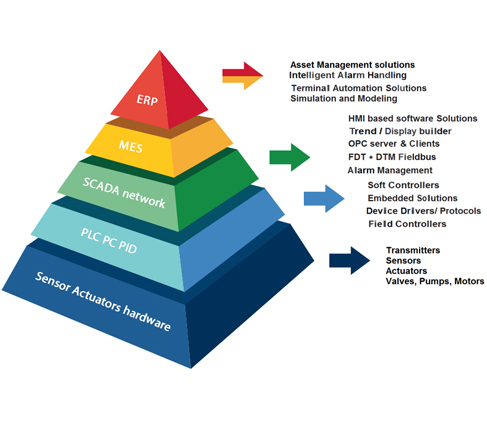

Introduction to data communications

Basic principles

Data communications standards

ISO OSI model

Communications media

Modems

Error detection

Local Area Networks

Modbus

HART

Actuator Sensor Interface (ASI)

CANBus /DeviceNet

Profibus

Foundation Fieldbus

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| IE122-02 | 12-04-2026 | Muscat | USD 5450 | |

| IE122-03 | 16-08-2026 | Amman | USD 5450 | |

| IE122-04 | 08-11-2026 | Manama | USD 5450 |

The Windows version of the Wien Automatic System Planning Package (WASP-IV) is the premier power systems expansion model used by utility planners, ministries, lending agencies, and research institutio ...

This course teaches both justification of automation projects -- including how to identify benefits and how to scope the project; and also best practices for structuring and leading the project execut ...

There are no particular prerequisites like programming knowledge etc. to take up this RPA. The audience who are subject matter expertise will be added an advantage to kick-start career in this field

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info