Upon successful completion of this course, participants will be able to:

By the end of this course delegates will learn about:

Design engineers, Inspection engineers and technicians, process engineers, welding engineers, welding inspectors and other welding personnel, maintenance engineers and technicians, manufacturing engineers, product development engineers and managers, mechanical engineers with or without experience in metallurgy / failure analysis. Others who may benefit from this training course are commercial liability insurance underwriters and claims adjusters and trial lawyers specializing in product liability cases.

Discussion of failure examples encountered by the participants

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| FAC131-02 | 19-04-2026 | Dubai | USD 5450 | |

| FAC131-03 | 13-07-2026 | Istanbul | USD 5950 | |

| FAC131-04 | 19-10-2026 | Kuala-Lumpur | USD 5950 |

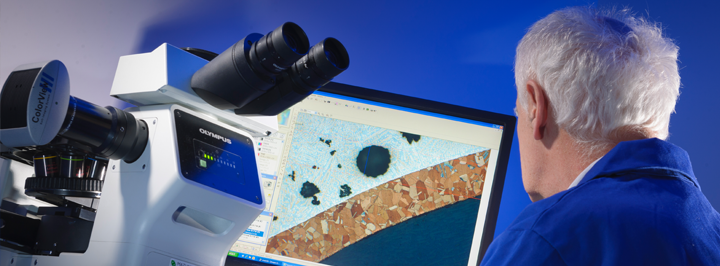

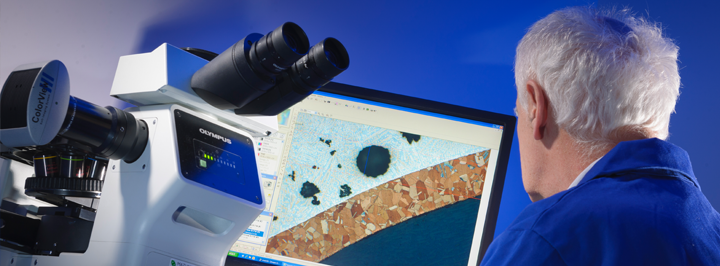

This course presents a history of metals and the background on the origins of various metals. It provides an explanation of physical characteristics of metals, including the reason metals behave diffe ...

The first step in safety and reliability of refinery equipment is identifying, understanding, preventing the relevant fail¬ure mechanisms. Corrosion is the primary cause of fail¬ure of components in t ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info