.jpg)

.jpg)

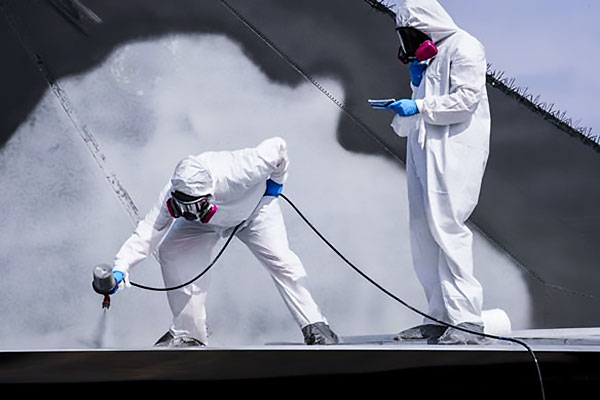

This course will identify the benefits of using coating systems for internal and external of pipes, vessels and tanks in a wide range of industries. It discusses performance benefits, application techniques. Comparisons are made with different types of coating materials. The characteristics of specialized internal and external coatings in oil and gas industries are also described, presenting data, supported by case histories, to illustrate the advantages for various service requirements: such as effective protection, decrease in friction and improved throughput.

By the end of this course delegates will learn about:

Mechanical Maintenance Engineers, Technicians, Supervisors, Foremen, Contractors, engineers, Inspectors, Consultants, Facility Owners, Technical Services and Sales Representatives

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| FAC126-02 | 12-04-2026 | Dubai | USD 5450 | |

| FAC126-03 | 21-09-2026 | Istanbul | USD 5950 | |

| FAC126-04 | 13-12-2026 | Muscat | USD 5450 |

PCS 1 Basic Principles provides an introduction of coatings and linings used to control corrosion as well as the economic benefits of managing them. This course defines and examines common coatings us ...

This course provides advanced level technology topics related to protective coatings. Highlights include an in-depth discussion of coatings, their basic chemical properties and any unique consideratio ...

This course explains all fundamental principles of fitness for service, their practical application through case histories, and a step by step evaluation process for each type of degradation mechanism ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info