This course will feature:

By the end of this course, delegates will be able to:

Drilling Engineers, Senior Drilling Engineers, Drilling Supervisors, Drilling Superintendents, Petroleum Engineers, Completion Engineers, Tool Pushers, Reservoir and Senior Reservoir Engineers, Geologists, Production and Completion Engineers, Foremen, Workover Engineers, Petroleum Engineers, Completion Engineers, Tool Pushers, Reservoir and Senior Industry Personnel, Lifting Personnel, Maintenance Engineers, Technologists, Mud Engineers, Well Site Supervisors, Drilling Contractors, Drilling Supervisors, Completion Engineers, Completion Supervisors, Drilling Managers, Drilling Technical Support Personnel, Trainee Drillers, Rig Engineers, Industry Personnel

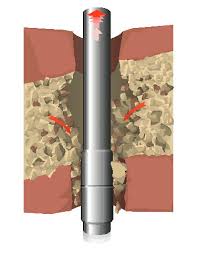

Rock Mechanics

Wellbore Stability

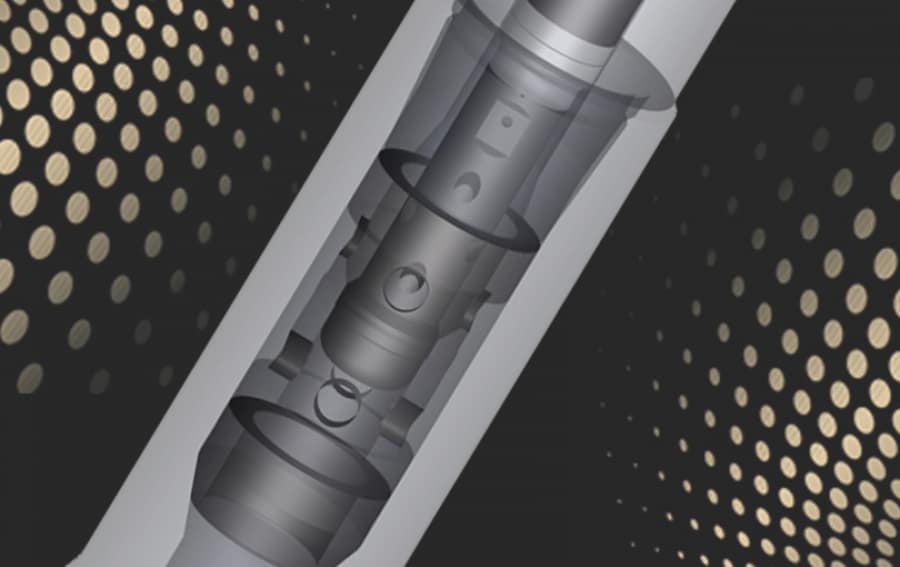

What is Stuck Pipe?

What Causes Stuck Pipe?

Types of Sticking

Differential Sticking

Warning Signs

Prevention Plan

Have a Stuck Pipe Prevention Plan

Fishing Operations

Broken Bit Cases

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| DE177-02 | 19-04-2026 | Dubai | USD 5450 | |

| DE177-03 | 19-07-2026 | Muscat | USD 5450 | |

| DE177-04 | 19-10-2026 | Kuala-Lumpur | USD 5950 |

This Stuck Pipe Prevention & Fishing Operations seminar provides a comprehensive coverage in the industry for understanding and preventing the underlying causes of Stuck Pipe, Wellbore Instability, Lo ...

It is estimated that approximately US$ 2 billion are wasted annually on stuck pipe. Furthermore it is believed that 80 – 85% of these stuck pipe incidents are preventable. The course focuses on the ke ...

This course provides a treatment of the causes of stuck pipe concentrating on poor hole cleaning as a primary cause. Also, it covers and the techniques employed to avoid such problems. This course cov ...

This course will be all about prevention rather than cure. It will teach the complete process of detection, diagnostics, and resolution in a methodical way. The candidates will be working in teams to ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info