By the end of this course delegates will be able to:

Drilling Engineers, Senior Drilling Engineers, Drilling Supervisors, Workover Engineers, Petroleum Engineers, Completion Engineers, Tool Pushers, Reservoir and Senior Reservoir Engineers, Geologists, Production Engineers & Technologists, Wellsite Engineers, Lifting Personnel, Maintenance Engineers, Foremen, Industry Personnel

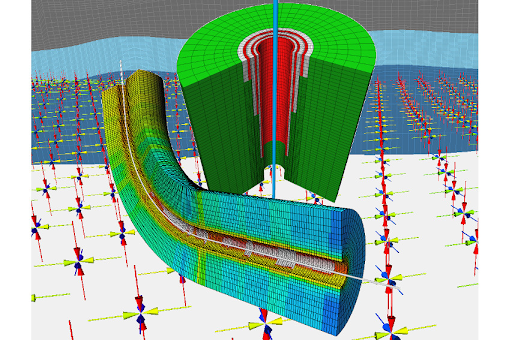

Drilling Mechanics

Drilling Dynamics

Bit Performance Optimization

System Optimization

Other Topics in Drilling Optimization

Course summary

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| DE170-02 | 20-04-2026 | Istanbul | USD 5950 | |

| DE170-03 | 06-09-2026 | Dubai | USD 5450 | |

| DE170-04 | 07-12-2026 | Kuala-Lumpur | USD 5950 |

The demands placed upon drilling fluids have increased dramatically over the last two or three decades. The drivers include reducing environmental impact, maximizing well productivity, accessing high ...

The integrity of the wellbore plays an important role in petroleum operations including drilling, completion and production. Borehole enlargement, stuck pipe, mud losses, casing collapse, compaction, ...

Specifications of drill string components, design methods for overload and fatigue including combined loads, calculation of working capacity, specification of inspection programs, and the use of Stand ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info