By the end of this course delegates will be able to:

Electrical Engineers, Power Generation Engineers, Power System Protection Engineers, Process Control Engineers & Personnel, Electrical and Instrumentation Technicians & Design Engineers, Maintenance Technicians & Supervisors, Plant Operators & Technicians, Oil & Gas Industry Personnel

CDGA attendance certificate will be issued to all attendees completing a minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| EE145-02 | 26-04-2026 | Dubai | USD 5450 | |

| EE145-03 | 26-07-2026 | Muscat | USD 5450 | |

| EE145-04 | 25-10-2026 | Riyadh | USD 5450 |

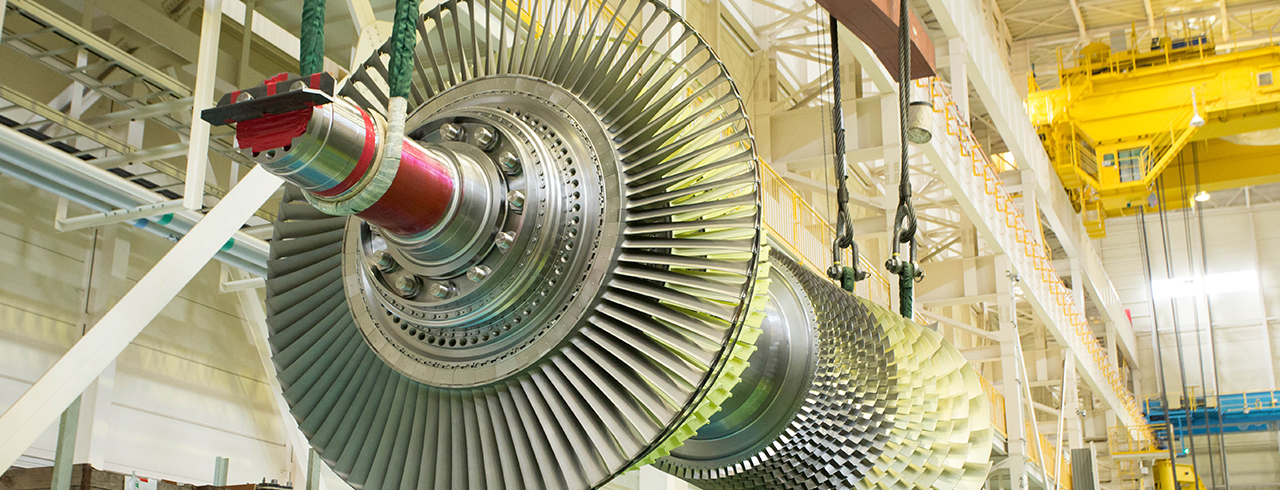

This course is an ideal course for those engineers/technicians wishing to gain a more detailed understanding of the mechanical design and maintenance activities associated with Gas Turbines. Together ...

The gas turbine is a versatile source of shaft or propulsion power in a growing number of applications. The course reviews methods for evaluating the performance of gas turbines, leading to the criter ...

This course will provide technical information for those people who maintain the gas turbine engines. The goal of each training program is to build confidence based on knowledge and understanding. Eng ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info