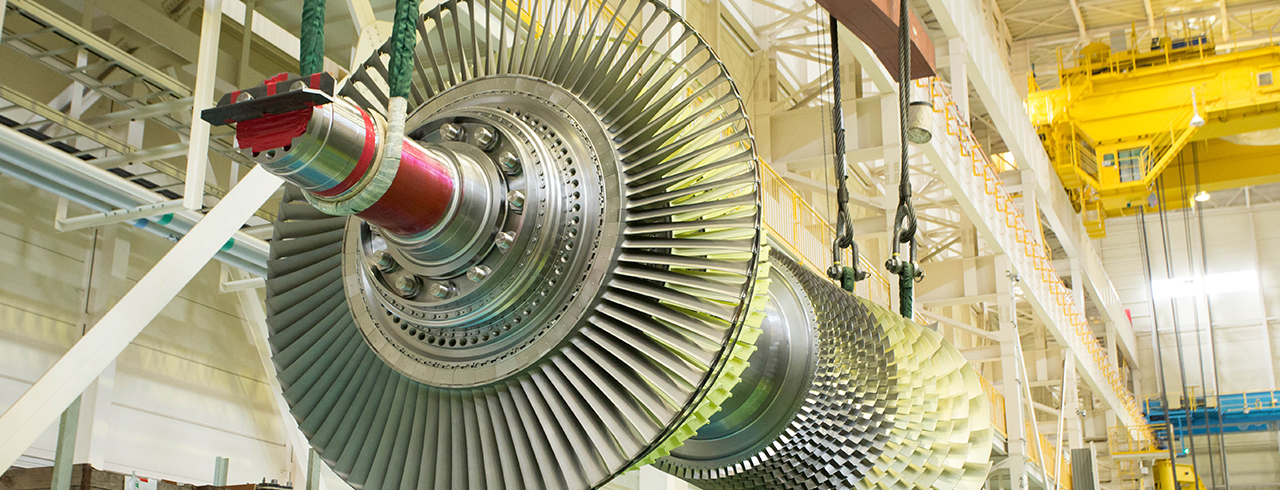

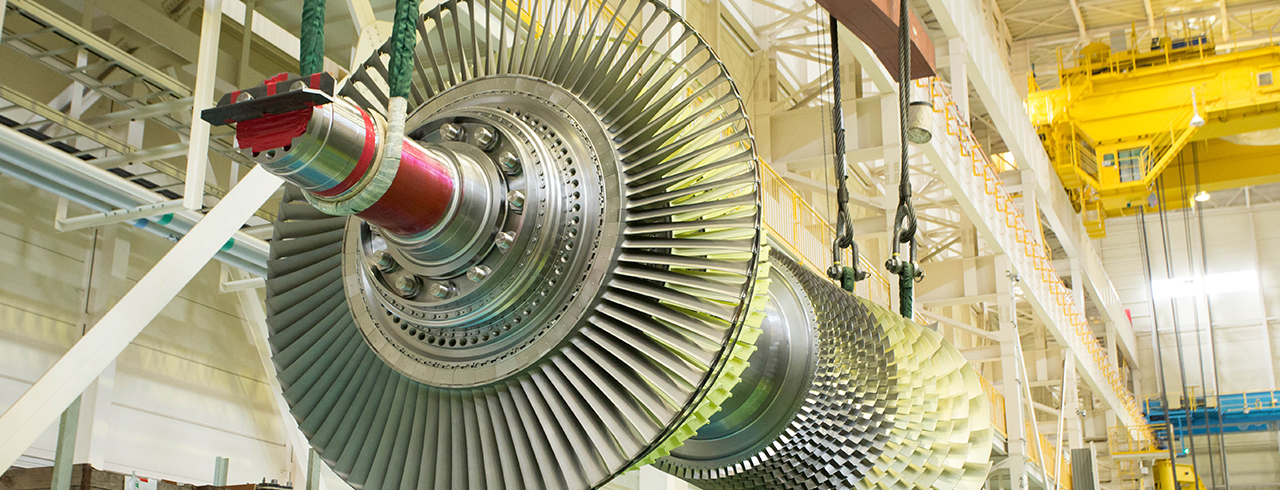

The objective of this course is to give participants an understanding of basic gas turbine operations and construction as well as a fundamental knowledge of proper operation, control and protection of the turbine and its accessory systems. The course does not include any discussions of generators.

By the end of this course delegates will be able to:

Electrical Engineers, Power Generation Engineers, Mechanical Maintenance Personnel, Power System Protection Engineers, Gas turbine newcomers and more experienced persons who desire an overview of the many available gas turbine technologies, Process Control Engineers & Personnel, Electrical and Instrumentation Technicians & Design Engineers, Maintenance Technicians & Supervisors, Plant Operators & Technicians, Oil & Gas Industry Personnel

CDGA attendance certificate will be issued to all attendees completing a minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| EE141-02 | 03-05-2026 | Muscat | USD 5450 | |

| EE141-03 | 03-08-2026 | Istanbul | USD 5950 | |

| EE141-04 | 01-11-2026 | Dubai | USD 5450 |

This course presents the nature and purpose of different modes of maintenance such as running, predictive, and preventive maintenance. It enables the candidates to apply the following concepts: mainte ...

This course is an ideal course for those engineers/technicians wishing to gain a more detailed understanding of the mechanical design and maintenance activities associated with Gas Turbines. Together ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info