This course covers the area of interest of industrial companies using natural gas through a pipe line and metering system. It, also, covers general information on gas properties and processing operations.

By the end of this CDGA training course, participants will be able to:

Gas measurement engineers, operators, technicians, analysts, senior and junior engineers and chemists, senior technicians, production engineers, petroleum engineers, and personnel who witness or audit natural gas measurement Professionals who have been allocated crisis management tasks yet have had insufficient time to devote to the subject

Natural Gas Fundamental

Raw Gas Transmission

Sales Gas Transmission

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| DE146-02 | 06-04-2026 | Istanbul | USD 5950 | |

| DE146-03 | 02-08-2026 | Dubai | USD 5450 | |

| DE146-04 | 06-12-2026 | Cairo | USD 5450 |

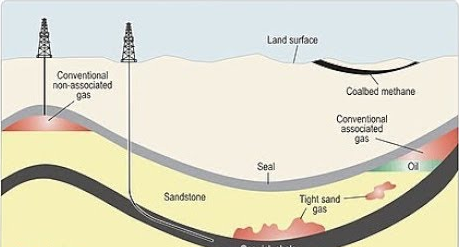

Historical and current background on the reserves, production, consumption, and storage of natural gas all over the world are given. Occurrences, and phase behavior of natural gases are reviewed. Natu ...

This five full-day course is designed to provide your valuable attendees with a comprehensive knowledge about Gas Lift design, operation, optimization, and troubleshooting in the oilfield. The course ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info