By the end of this course, delegates will be able to:

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

Day1

Day 2

Day 3

Day 4

Day 5

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI152-02 | 13-04-2026 | Istanbul | USD 5950 | |

| MI152-03 | 12-07-2026 | Doha | USD 5450 | |

| MI152-04 | 26-10-2026 | Kuala-Lumpur | USD 5950 |

This aims to convey the latest thinking and best practice of machinery vibration monitoring and analysis via lectures, case studies, video films, and friendly software and course activities. The cours ...

Pumps and compressors are the tow pieces of equipment which are used in almost all manufacturing and processing plants. The effectiveness of their selection, specifications, operations, maintenance an ...

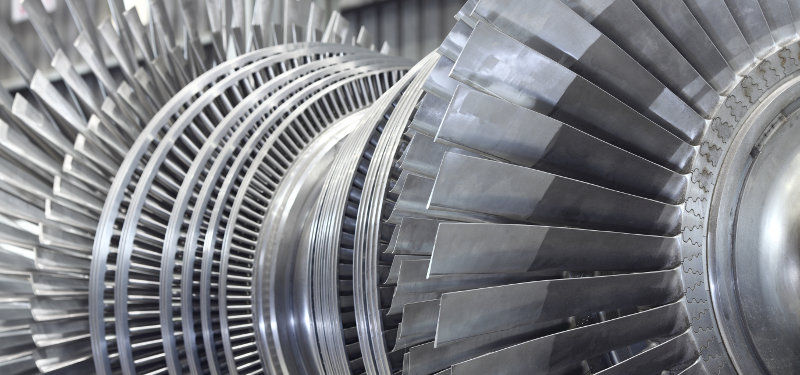

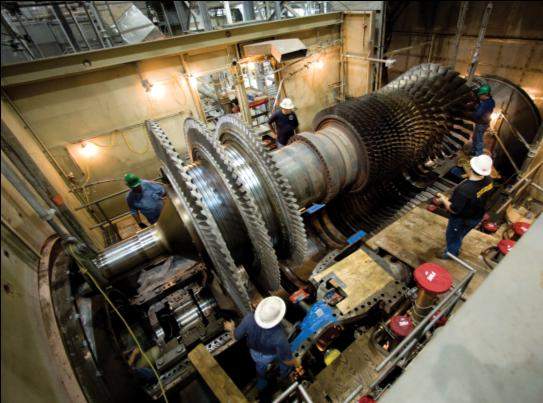

Rotating Equipment's are the pieces of equipment which are used in almost all manufacturing and processing plants. The effectiveness of their selection, specifications, operations, maintenance and tro ...

Rotating equipment is essential for gas and oil processing plants. The designers as well as the operating and maintenance staff are usually confronting with major issues regarding the reliability, opt ...

Pumps and compressors are the tow pieces of equipment which are used in almost all manufacturing and processing plants. The effectiveness of their selection, specifications, operations, maintenance an ...

This course will introduce delegates to different types of pumps, compressors, turbines and associated equipment, such as bearings, seals, filters, separators, etc. The focus in the course will be on ...

This course for industry aims to convey the latest thinking and best practice of machinery vibration monitoring and analysis via lectures, case studies, video films and program activities. The course ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info