This training course will feature:

By the end of this CDGA training course, participants will be able to:

Drilling Engineers, Senior Drilling Engineers, Drilling Supervisors, Drilling Superintendents, Petroleum Engineers, Completion Engineers, Tool Pushers, Reservoir and Senior Reservoir Engineers, Geologists, Production and Completion Engineers, Foremen, Work over Engineers, Petroleum Engineers,

Completion Engineers, Tool Pushers, Reservoir and Senior Industry Personnel, Lifting Personnel, Maintenance Engineers, Technologists, Mud Engineers, Well Site Supervisors, Drilling Contractors, Drilling Supervisors, Completion Engineers, Completion Supervisors, Drilling Managers, Drilling Technical Support Personnel, Trainee Drillers, Rig Engineers, Affiliate Technical Directors, Asset Managers, Petroleum Engineers, Production Technologists, Production Personnel, Production Operators, Maintenance Supervisors, Drilling and Well Servicing Personnel, Drilling Manager, Drilling/Well Engineers, Completion and Well Service Engineers, Drilling Supervisors, Rig Manager, Drillers, Industry Personnel

Basic Well Completion Design, Practices and Strategies

Packer Selection and Tubing Forces

Wellheads, Chokes, Sub-Surface Safety Valves and Flow Control Equipment

Well Integrity Life Cycle

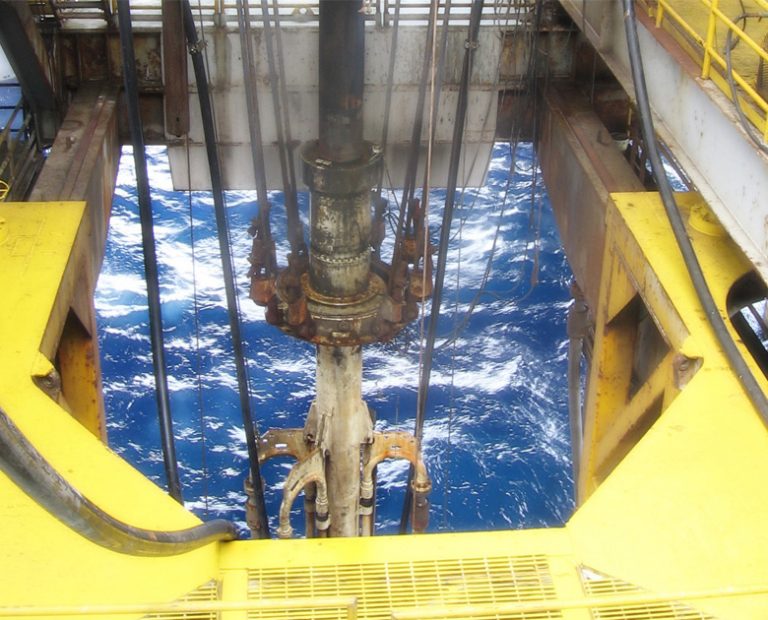

Deviated, Multiple Zone, Subsea, Horizontal, Multilateral and HPHT Completion

Sand Control

Well Stimulation Methods

Wire line, Coiled Tubing and Snubbing Operations

Coiled Tubing

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| DE138-02 | 01-06-2026 | Istanbul | USD 5950 | |

| DE138-03 | 06-09-2026 | Muscat | USD 5450 | |

| DE138-04 | 22-11-2026 | Dubai | USD 5450 |

The Advanced Completions and Workovers course is an introduction to many facets of completion and intervention technology. The material progresses through each of the major design, diagnostic and inte ...

This course addresses the needs of engineers in both well completion and workover. It will focus on building the current foundation of engineers on completion and workover techniques, but will further ...

This course is primarily designed for drilling, production and completion engineers and supervisors needing a practical understanding and an appreciation of well completion design and operation, well ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info