.jpg)

.jpg)

By the end of this training course, participants should be able to:

The training instructor relies on a highly interactive training method to enhance the learning process.

The course material is rich with various training tools that ensure all participants gain a

complete understanding of all the topics covered. The training environment is highly

stimulating, challenging, and effective for all trainees to participate, share their thoughts, and inquire about their in-house challenges.

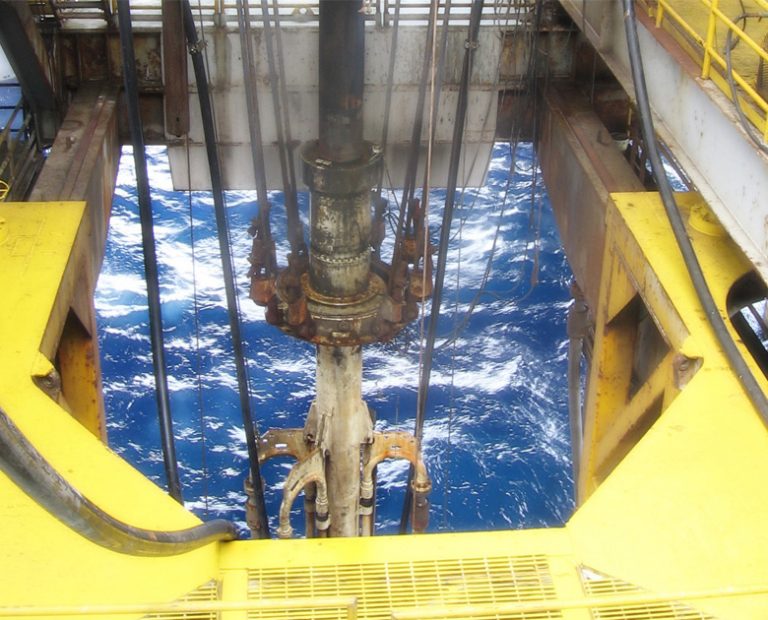

Module One: Introduction to Well Integrity

Module Two: Well Integrity Barriers Throughout Well Life Cycle

▪ Barrier Requirement, Performance Standards, and Operating Limits

▪ Verification and Acceptance Criteria of Well Barriers

▪ Casing, Cement, Completion, Wellhead, and X-tree Integrity Requirements

▪ Zonal Isolation Objectives and Requirements

▪ Material Selection Guidelines

▪ Barrier Verification Including Pressure Testing and Function Testing

▪ API Acceptable Leaking Rate and Risk-Based Approach of Verification

▪ Requirements of Breaking Containment

▪ Handover Process

▪ Temporary and Permanent Plug and Abandonment

▪ Barrier Requirements, Verification, and Acceptance Criteria for Permanent P&A

▪ Options, Considerations, and Procedure for Setting Cement Plugs

▪ Different Material Types for Permanent Barriers

▪ Challenges and Barrier Failure Modes after P&A

Module Three: Elements of Well Integrity Management System

Module Four: Well Integrity Diagnosis, Monitoring, and Preventive Maintenance

Module Five: Flow Assurance Issues, Industry Trends and New Technologies

1. Mirroring Software Capabilities to Overall Course Content

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| DE137-02 | 05-04-2026 | Dubai | USD 5450 | |

| DE137-03 | 20-07-2026 | Istanbul | USD 5950 | |

| DE137-04 | 15-11-2026 | Doha | USD 5450 |

This course addresses the needs of engineers in both well completion and workover. It will focus on building the current foundation of engineers on completion and workover techniques, but will further ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info