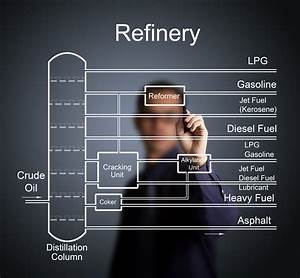

This course will guide the participants to develop key concepts and techniques to operate, select and optimize refinery catalytic processes. These key concepts can be utilized to make design and operating decisions.

Training and development is an investment in future success – give your employees the keys to success. This course covers a general overview of the Catalytic Processes in a Refinery and how each integrates with the high value products, with a special emphasis on Fluidized Catalytic Crackers, and Catalytic Reformers. A history of each Catalytic Process will be reviewed including; process description, process variables, reaction chemistry, catalyst development and evaluation.

People who are making day to day decisions regarding operation, design,

Maintenance, and economics of process industry plants.

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

Day One:

Introduction

Alkylation

Feedstock, Reaction, Catalyst

Hydrogenation

Feedstock, Reaction, Catalyst

Dehydrogenation

Feedstock, Reaction, Catalyst

Day Two

Isomerization

Feedstock, Reaction, Catalyst

Hydrocracking and De-Alkylation

Feedstock, Reaction, Catalyst

Day Three

Fluidized Catalytic Cracking

Feedstock, Reaction, Catalyst

Day Four

Hydrodesulfurization

Feedstock, Reaction, Catalyst

Day Five

Catalytic Reforming

Feedstock, Reaction, Catalyst

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| PE140-02 | 19-04-2026 | Dubai | USD 5450 | |

| PE140-03 | 19-07-2026 | Muscat | USD 5450 | |

| PE140-02 | 18-10-2026 | Doha | USD 5450 |

This five-day course is designed for blending engineers, senior operators, product coordinators, refinery planners, refinery lab personnel, and fuels marketers and traders, and provides a comprehensiv ...

Process engineering is at the heart of much of the chemical, oil, gas, and petrochemical industries. It requires familiarity not only with chemical engineering principles, but also with many of the ot ...

The course is designed as a comprehensive and practical refining overview covering a range of complexities from simple topping units to extremely complex high-conversion refineries with aromatics prod ...

This Production Planning & Scheduling in Petroleum Refineries training course is specifically designed to identify and resolve issues of production planning and scheduling in petroleum refineries that ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info