This course will cover fluid flow in pipes (both single and multiphase flow), the theoretical bases of interpretation of production logging PLT.

By the end of this course delegates will be able to:

Geologists, Geophysicists, Petrophysicists, Stratigraphers, Geochemists, Sedimentologists, Reservoir, Petroleum, Wellsite Geologists, Petroleum Engineers, Drilling Engineers, Reservoir Engineers, Production Engineers, Operations Engineers, Technologists, Log Analysts, E&P Personnel, Exploration & Development Personnel, Surveillance Engineers, Geologists, Reservoir Engineers, Seismic Interpreters, E&P Managers, Data Management and Oil & Gas Personnel

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| GE104-02 | 03-05-2026 | Muscat | USD 5450 | |

| GE104-03 | 16-08-2026 | Riyadh | USD 5450 | |

| GE104-04 | 09-11-2026 | Kuala-Lumpur | USD 5950 |

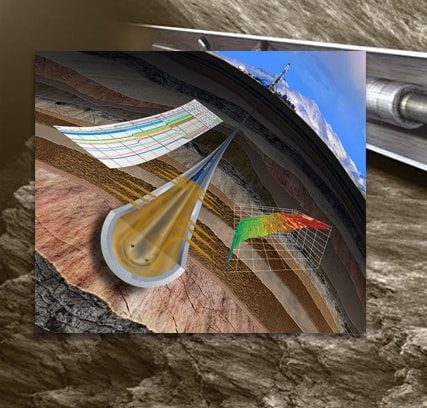

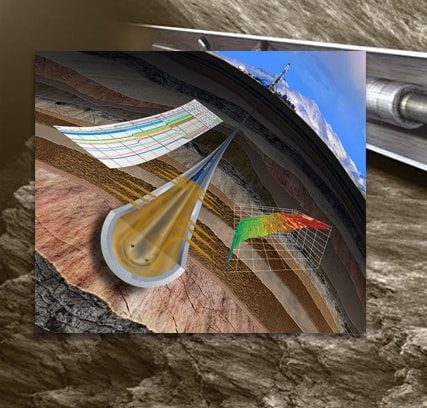

Cased-hole logging involves retrieving logging measurements through the well casing, or the metal piping that is inserted into the well during completion operations. Cased-hole logging is performed mo ...

This course will provide the candidates with the fundamentals and language of petroleum geology, exploration, drilling and production. This understanding will enable you to communicate more efficientl ...

This course will cover the new and traditional wireline diagnostic techniques for the surveillance of cased wells. Cased hole and production log evaluation, plus a loose-leaf workbook, are provided to ...

This course discusses the fundamental theories that are critical in current well designs and well instability problems. It looks at the issues of rock properties, subsurface stresses and methods for t ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info