Participants will learn to:

Who should attend:

Target Competencies:

Training Deliverables:

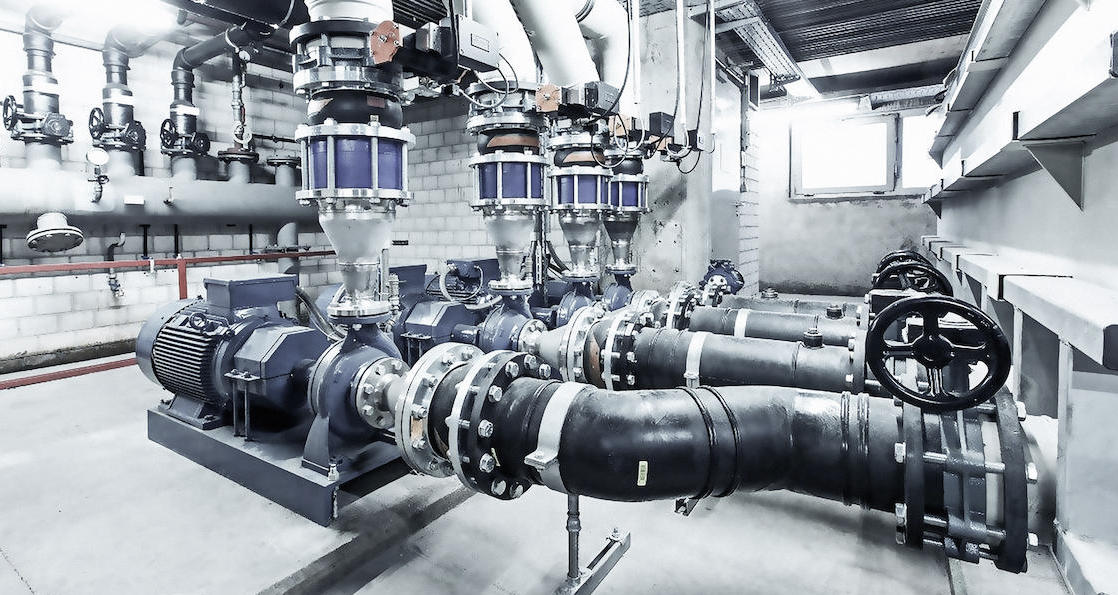

Day 1 – Pump Fundamentals for Petrochemical Applications

Exercise: Select suitable pump types for 3 different petrochemical fluids

Day 2 – Piping Systems and Flow Design

Workshop: Calculate pressure drop for a high-viscosity fluid transfer line

Day 3 – System Integration, Hazards & Control

Activity: Create a system layout that includes tank, pump, valve, and safety devices

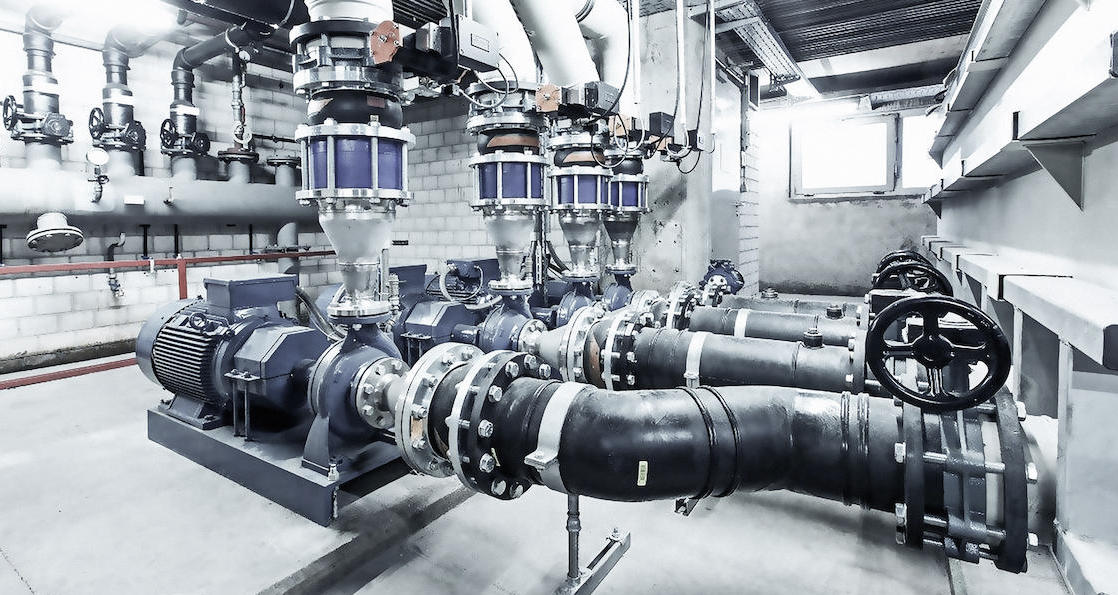

Day 4 – Troubleshooting, Reliability & Maintenance

Case Study: Analyze failure data to propose a preventive maintenance schedule

Day 5 – Energy Efficiency, Smart Monitoring & Best Practices

Final Exercise: Redesign an inefficient system using performance and failure data

CDGA attendance certificate will be issued to all attendees completing a minimum of 75% of the total course duration

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI265-02 | 20-04-2026 | Kuala-Lumpur | USD 5950 | |

| MI265-03 | 12-07-2026 | Dubai | USD 5450 | |

| MI265-04 | 06-12-2026 | Manama | USD 5450 |

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info