This course aims to enable the participant to:

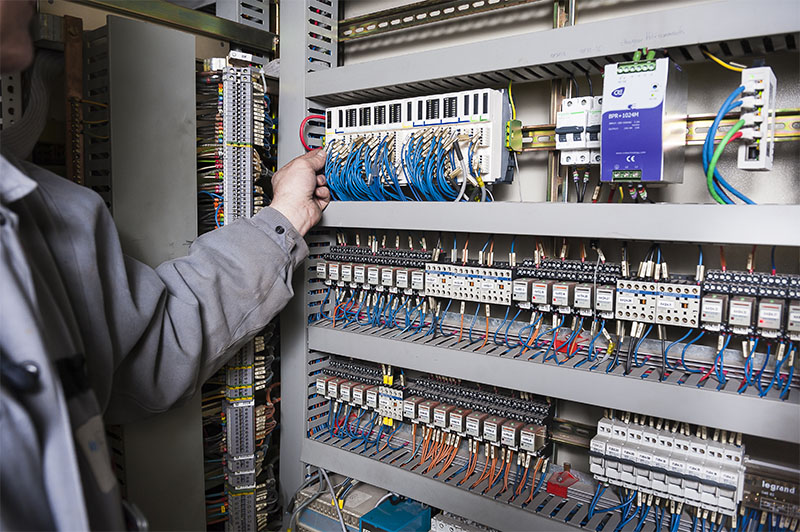

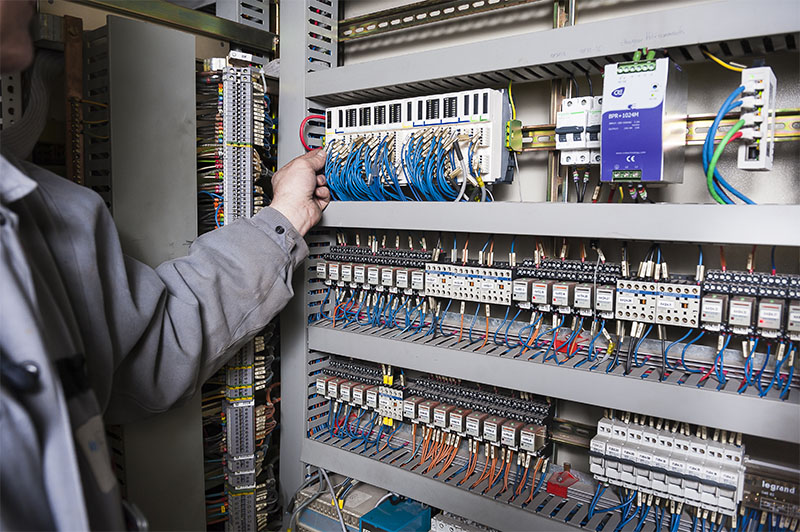

Technological advances in recent years have resulted in the development of the programmable logic controller and a consequential revolution of control engineering. This course is an introduction to programmable logic controllers and aims to ease the tasks of practicing engineers coming first into contact with programmable logic controllers, and as an introduction for first year undergraduate courses in engineering. The course addresses the problem of different programmable control manufacturers using different nomenclature and program forms by describing the principles involved and illustrating them with examples from a range of manufacturers. The text includes:

1) Programmable logic controllers

2) Input-output devices

3) Number systems

4) I/O processing

5) Ladder and functional block programming

6) IL, SFC and ST programming methods

7) Internal relays

8) Jump and call

9) Timers

10) Counters

11) Shift registers

12) Data handling

13) Designing systems

14) Programs

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| IE114-02 | 06-04-2026 | Kuala-Lumpur | USD 5450 | |

| IE114-03 | 02-08-2026 | Cairo | USD 5450 | |

| IE114-04 | 04-10-2026 | Amman | USD 5450 |

SCADA has traditionally meant a window into the process of a plant and/or a method of gathering of data from devices in the field. Today the focus is on integrating this process data into the actual b ...

Industrial data communication is characterized by its operating environment. Electromagnetic interference (EMI), long distances and physical barriers set industrial communications apart from typical b ...

In modern manufacturing and industrial processes, petroleum industries, utilities, petrochemical and pipeline industries, telemetry is often needed to connect equipment and systems separated by large ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info