The course provides the candidates with the knowledge needed to be effective in the inspection, monitoring and diagnostics of pumps and compressors, with emphasis placed upon the importance of a combined condition monitoring and strip-down inspection approach to maintenance. It will investigate the root causes of failure, and relates these to operating conditions and process parameters. Design, installation, lubrication and wear related failure mechanisms are identified and a detailed understanding of the troubleshooting and diagnostic methods needed to detect and identify these is developed.

By the end of this course delegates will be able to:

Engineers, Supervisors, Technicians, Foremen and technical staff involved in the monitoring, predictive maintenance and diagnostics of pumps and compressors

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI216-02 | 12-04-2026 | Manama | USD 5450 | |

| MI216-03 | 27-07-2026 | Kuala-Lumpur | USD 5950 | |

| MI216-04 | 13-12-2026 | Dubai | USD 5450 |

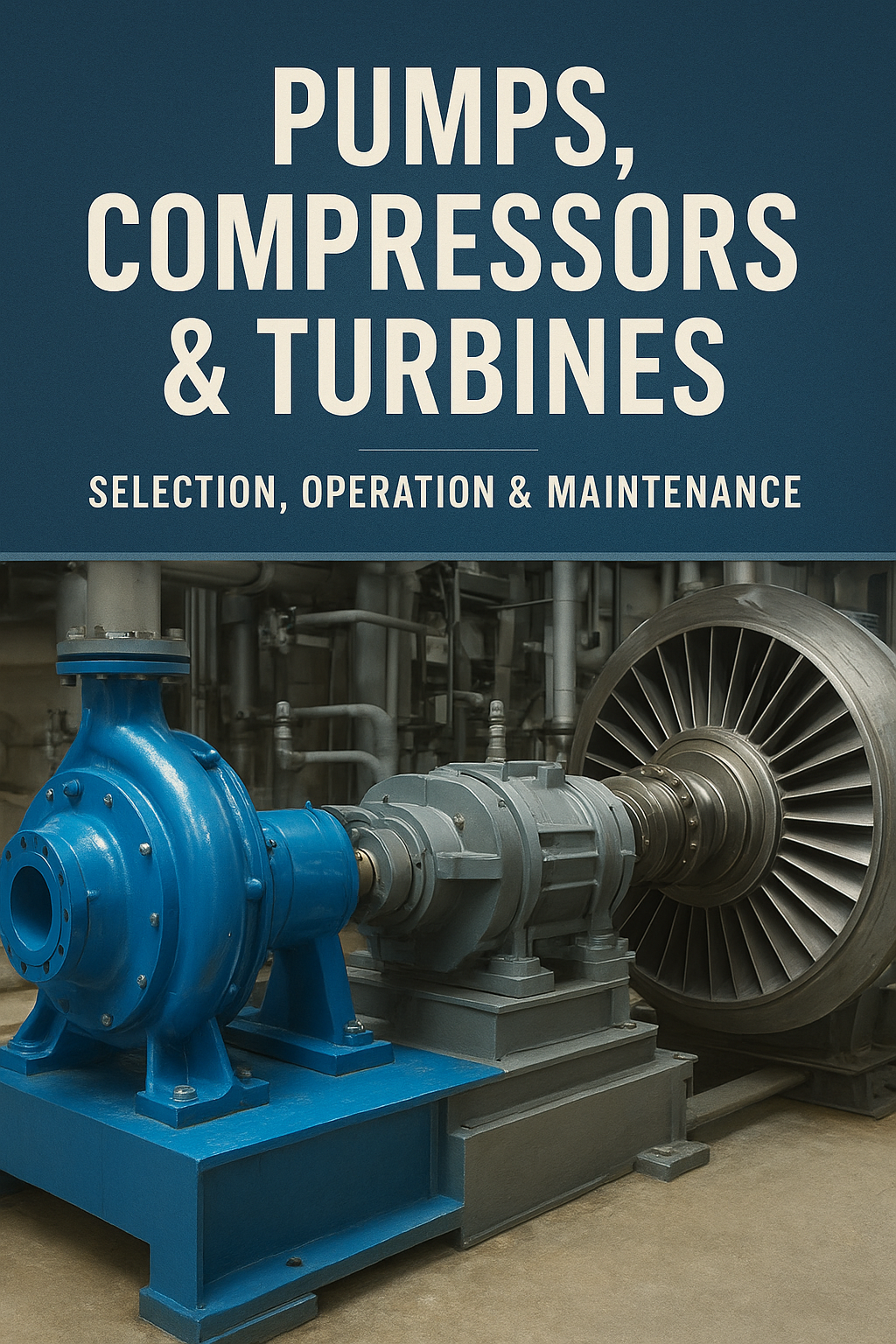

This course is to provide the trainees with a strong background in the field of Advanced Rotating Equipment (Pumps, Compressors, and turbines) maintenance and troubleshooting. In addition, the traine ...

A complete understanding of construction details and functioning of pumps, compressors and turbines is a prerequisite for successful operation of plant and piping system. This is especially important ...

Pumps and compressors are essential components in almost all industries in that they are required to meet system demands and operate reliably. Further, since they can consume approximately 30% of a pl ...

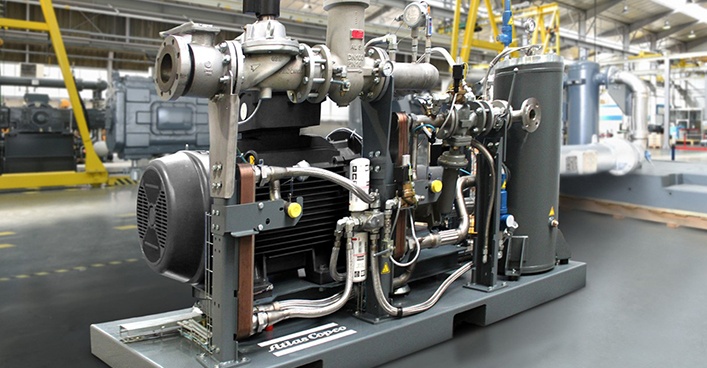

This programme provides a comprehensive understanding of the various types of reciprocating, rotary, and dynamic compressors and pumps. This includes trunk piston, sliding crosshead piston, diaphragm ...

The course will introduce participants to the different types of pumps and their associated terminology. Centrifugal and positive displacement pumps, packing, mechanical seals and sealing systems, bea ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info