This program provides a practical approach to conducting risk assessments demonstrating how reliable occupational health & hygiene data should be collected and used to make decisions on health risks from chemical substances.

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

Monitoring Exposure - Theory and Practice

Interpretation and use of exposure data

Assessment of engineering controls

Personal Protective Equipment (PPE)

Health surveillance & Case Studies

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| HSE217-02 | 31-05-2026 | Manama | USD 5450 | |

| HSE217-03 | 16-08-2026 | Dubai | USD 5450 | |

| HSE217-04 | 22-11-2026 | Doha | USD 5450 |

Who should attend? This course is suitable for anyone involved with chemicals policy, chemical management and chemical risk assessment and also any involved in chemical handling, storage and transpor ...

Emergency responders are those people who may be the first emergency personnel to arrive at hazardous material/waste incidents and are expected to take some evasive actions to protect the people or th ...

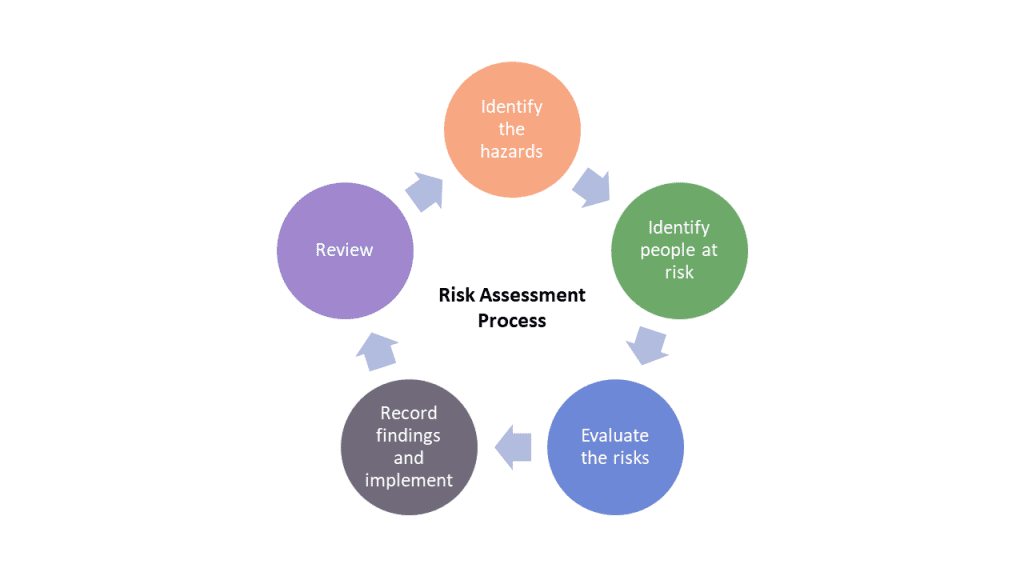

Introduction: Traditional’ risk assessment programs exist to identify hazards arising from work activities to ensure suitable risk control measures are in place. However, incidents continue to happen ...

Managing risk is increasingly being recognized as a critical management skill. Risk uncertainty, assessment, and management, when used correctly is a highly effective problem solving tool for line- m ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info