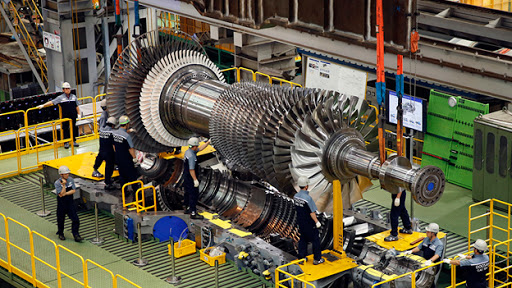

This programme provides an in-depth understanding of all the equipment and systems used in steam power plants, gas turbines, co-generation, combined cycle plants, wind farms, and solar power generating plants. Computer simulation, design, selection considerations, operation, testing, maintenance and economics of all these power generating plants as well as emission limits, monitoring and governing systems will also be covered thoroughly.

This programme examines the advantages and disadvantages of each type of power generating plants. The reliability, life cycle cost, profitability, refurbishment, and life extension methods of each type of power generating plants are also covered in detail.

The instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all the delegates gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective. The participants will learn by case studies. They will be able to apply all the concepts to their own organization.

DAY 1 - Steam Power Plants

DAY 2 - Steam Turbines and Auxiliaries

DAY 3 - Gas Turbines & Compressors

DAY 4 - Co-generation Plants, Wind and Solar Power Generation

DAY 5 - Transformers & Generators

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI195-02 | 31-05-2026 | Muscat | USD 5450 | |

| MI195-03 | 17-08-2026 | Indonesia | USD 5950 | |

| MI195-04 | 15-11-2026 | Cairo | USD 5450 |

Upon completion of this course, participants will gain a basic understanding of the main components and subsystems of gas turbine systems, steam power plants, co-generation, and combined cycle plants. ...

The addition of gas turbine-based combined cycle power plants to supply new generating capacity continues to play a major role in the power industry. This technology is being adopted by all key player ...

The aim of this course is to provide the participants with a complete and up‐to‐date overview of domains concerning Photovoltaic’s (PV) with emphases on design, installation, operation & maintenance. ...

This course depicts the factors to be considered within the area of power generation. It will begin with an overview of generator design and function. Load requirements and calculations including load ...

Reliability and availability of combined cycle power plants can be a matter of skilled routine operations and maintenance activities. These skilled routine operations and maintenance personnel begin t ...

In recent years, the power generation industry has had to face major structural changes following privatization and liberalization of the electricity markets. This new business environment has led to ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info