The candidates will be able to understand: PSM and its history, who is covered by such a program, the PSM team process, the elements of a properly designed PSM program and how to begin the process, the basics of how PSM and the EPA’s Risk Management Plans (RMP) work together.

By the end of this course delegates will be able to:

Supervisors, Engineers, PSM Implementation Team Members (Anyone involved with implementation, including operators and maintenance personnel), Compliance Auditors, Environmental Management and Technicians

Course Intro & Case Study Introduction

CDGA attendance certificate will be issued to all attendees completing minimum of 75% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| HSE161-02 | 17-05-2026 | Amman | USD 5450 | |

| HSE161-03 | 16-08-2026 | Cairo | USD 5450 | |

| HSE161-04 | 08-11-2026 | Muscat | USD 5450 |

.jpg)

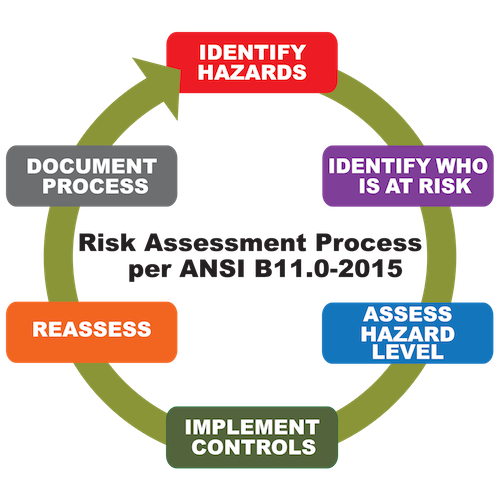

The foundation of any successful process safety program is a current set of process hazard analyses (PHAs) for each of its processes. Revalidating PHAs to keep them up to date and applicable is a must ...

When it is required identify and quantify hazards and potential accident scenarios associated with hazardous processes, it may be necessary to conduct a process risk analysis. Conducting this analysis ...

.jpg)

This course will assist companies to reduce risk and avoid losses reducing from the unintended releases of toxic, reactive, or flammable liquids and gases in processes involving highly hazardous mater ...

In today’s dynamic industrial landscape, the need to minimize risks and prevent accidents is more critical than ever. This course will guide you through proven methodologies for hazard analysis, risk ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info