– Level 2.jpg)

– Level 2.jpg)

This CDGA course will feature:

By the end of this CDGA training course, participants will be able to:

All personnel concerned with well intervention operations (wire-line, coiled tubing, snubbing, work-over) involved in operations linked to the detection of a kick: engineers, supervisors and operators who have to supervise or carry out well intervention operations

Completion Operations

Basic Principles & Well Fundamentals

Pressure Control Applied To Completion & Well Intervention

Completion Equipment

Different Types of Intervention with Their Respective Equipment

Wire Line Intervention

Coiled Tubing Operations

Snubbing Operations

Wireline Operations

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| DE164-02 | 07-06-2026 | Dubai | USD 5450 | |

| DE164-03 | 03-08-2026 | Istanbul | USD 5950 | |

| DE164-04 | 25-10-2026 | Amman | USD 5450 |

2.png)

This program is aimed at people who are in critical well control positions during well intervention operations. Participants must fulfill the prerequisite requirements of this course having IWCF level ...

This course is designed to fulfill the requirements for International Well Control Forum (IWCF) Well Intervention Pressure Control Qualification. It is assumed that the individual attending this cours ...

- Level 3-4.jpg)

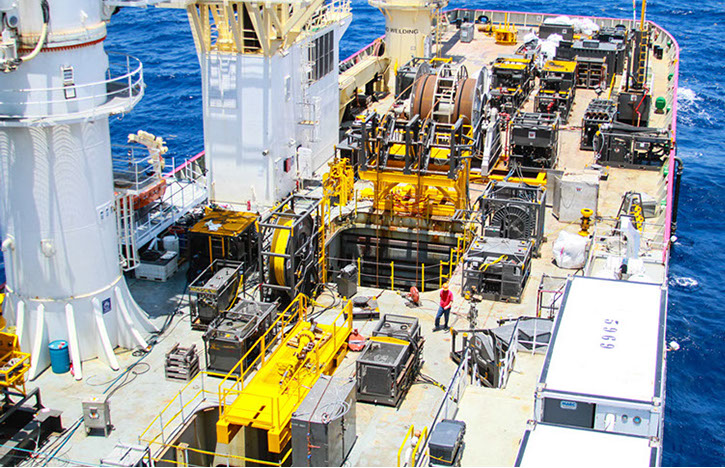

The course is designed for operators, engineers and supervisors and provides the knowledge and skills necessary to effectively and safely control a well during well intervention operations. This cours ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info