The course is designed for professionals who want to know comprehensively how is the best practice in implementing chemical EOR projects:

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

DAY 1 & DAY 2

Day 1 begins with concepts about EOR such as incremental recovery and salinity. These are brief concepts to understand and select EOR methods.

Day 1 and Day 2 continue with polymer flooding. The key parameters of polymer flooding are polymer viscosity to improve mobility ratio, and permeability reduction to improve injection profile. Special cases will be discussed.

DAY 3

Day 3 covers the chemical EOR process – surfactant flooding. To carry out a field project, we need to know what lab tests we need to do; we need to understand the parameters which are related to the reduction of residual oil saturation such as capillary number, IFT and capillary desaturation curve.

DAY 4

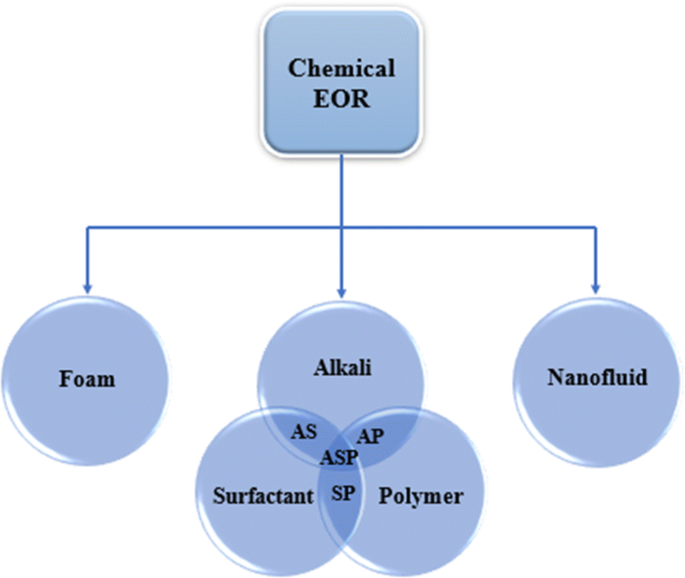

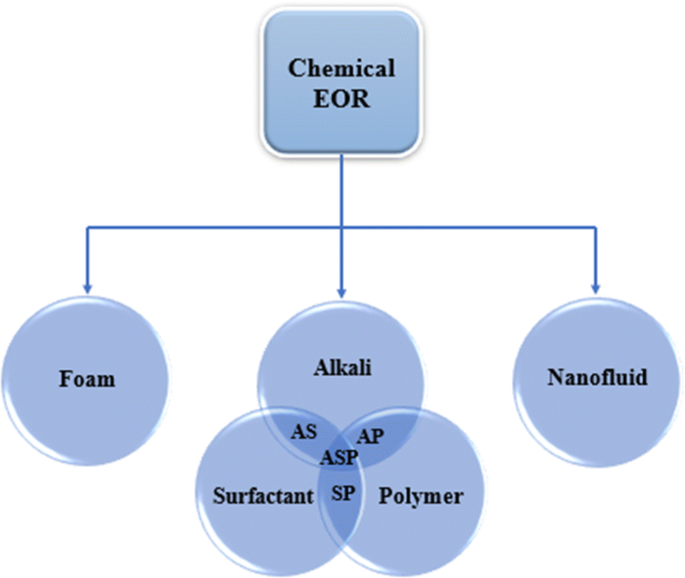

Day 4 first covers alkaline reactions, followed by combined methods. We focus on the important aspects of combined methods: their interactions and synergies. We will address some important questions such as why single alkaline flooding may not work well, why polymer is always needed.

DAY 5

Day 5 summarizes advantages and disadvantages of each method and combined methods, and focuses on the problems with ASP which are much less discussed in the literature. We will discuss some practical issues and answer the questions from the attendees which will give the attendees an opportunity to make the best use of this course.

CDGA attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| PE162-01 | 29-03-2026 | Doha | USD 5450 | |

| PE162-02 | 22-06-2026 | Istanbul | USD 5950 | |

| PE162-03 | 20-09-2026 | Dubai | USD 5450 | |

| PE162-04 | 06-12-2026 | Amman | USD 5450 |

The goal of this course is to provide attendants with solid basics of different aspects, types, and application of the three main types of Enhanced oil Recovery (EOR) processes. The three types of oil ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

CDGA keen to selects highly technical instructors based on professional field experience

Since CDGA was established, it considered a training partner for world class oil & gas institution

3012, Block 3, 30 Euro Business Park, Little Island, Co. Cork, T45 V220, Ireland

Mon to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info